Китайско-германское сотрудничество

Двухбалочный мостовой кран европейского типа

Разработано для точности и высокой производительности

Ключевые особенности

- Немецкие технологии: Оптимизированная конструкция с малой высотой потолка, легкой конструкцией и уменьшенным давлением на колеса, что позволяет минимизировать заводские инвестиции.

- Регулировка переменной частоты: Несколько вариантов скорости для точного подъема и перемещения (подъем 0,4–16 м/мин, перемещение тележки 3–30 м/мин).

- Надежное электроснабжение: Высокогибкие плоские кабели и С-образные рейки исключают риск обрыва провода.

- Повышенная безопасность: Электронные и механические противосходные устройства обеспечивают надежную работу.

- Синхронизированная операция: Двойное крановое соединение для синхронизированного хода, подъема и точного позиционирования.

Приложения

Разработано для универсальности в сложных условиях:

- Химическая промышленность: Безопасное обращение с опасными материалами.

- Металлургия: Надежный подъем тяжелых металлических компонентов.

- Автомобильный: Точное позиционирование крупных деталей.

- Железнодорожный: CRRC доверяет сборку локомотивов.

Технические характеристики

| Параметр | Спецификация |

|---|---|

| Грузоподъемность | До 800 тонн |

| Охватывать | До 49 м |

| Скорость подъема | 0,4-16 м/мин |

| Скорость движения тележки | 3-30м/мин |

| Скорость движения крана | 5-90 м/мин |

| Система управления | Регулирование частоты, синхронизированная работа |

| Источник питания | 380 В/50 Гц (настраивается) |

Примечание: Все параметры могут быть адаптированы к конкретному объекту и условиям работы.

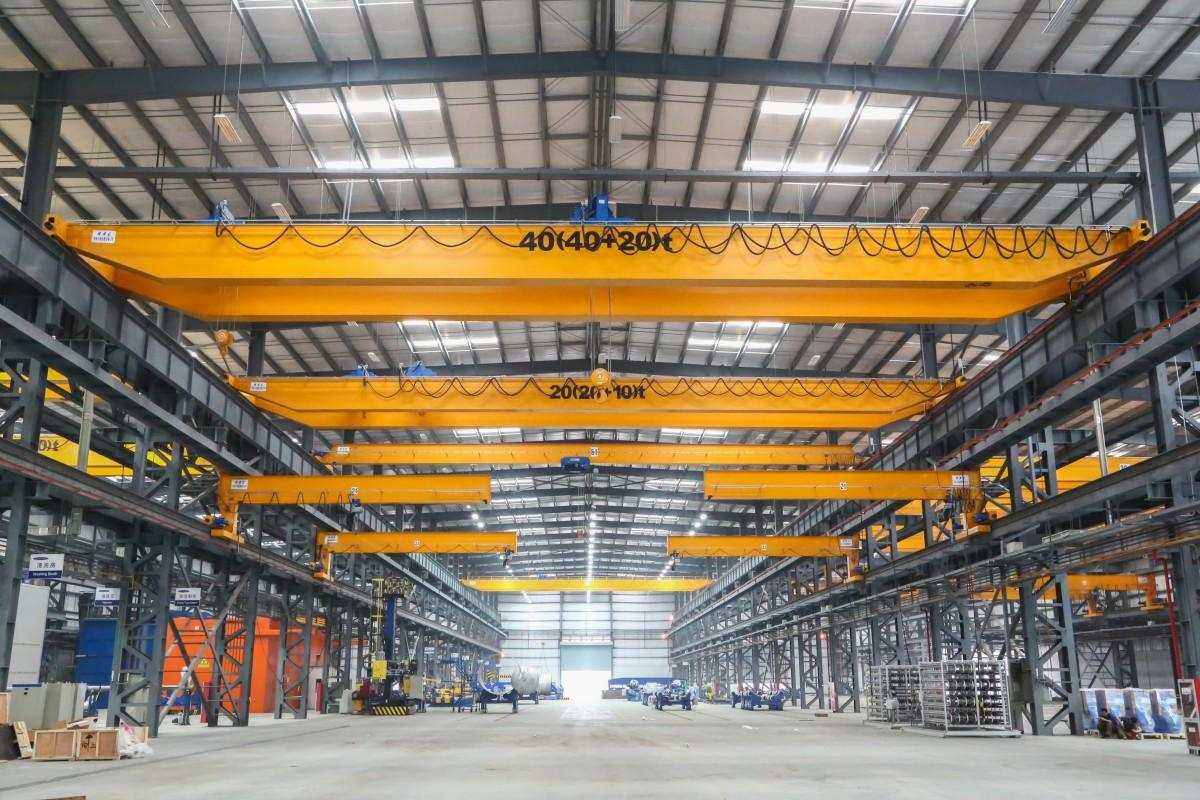

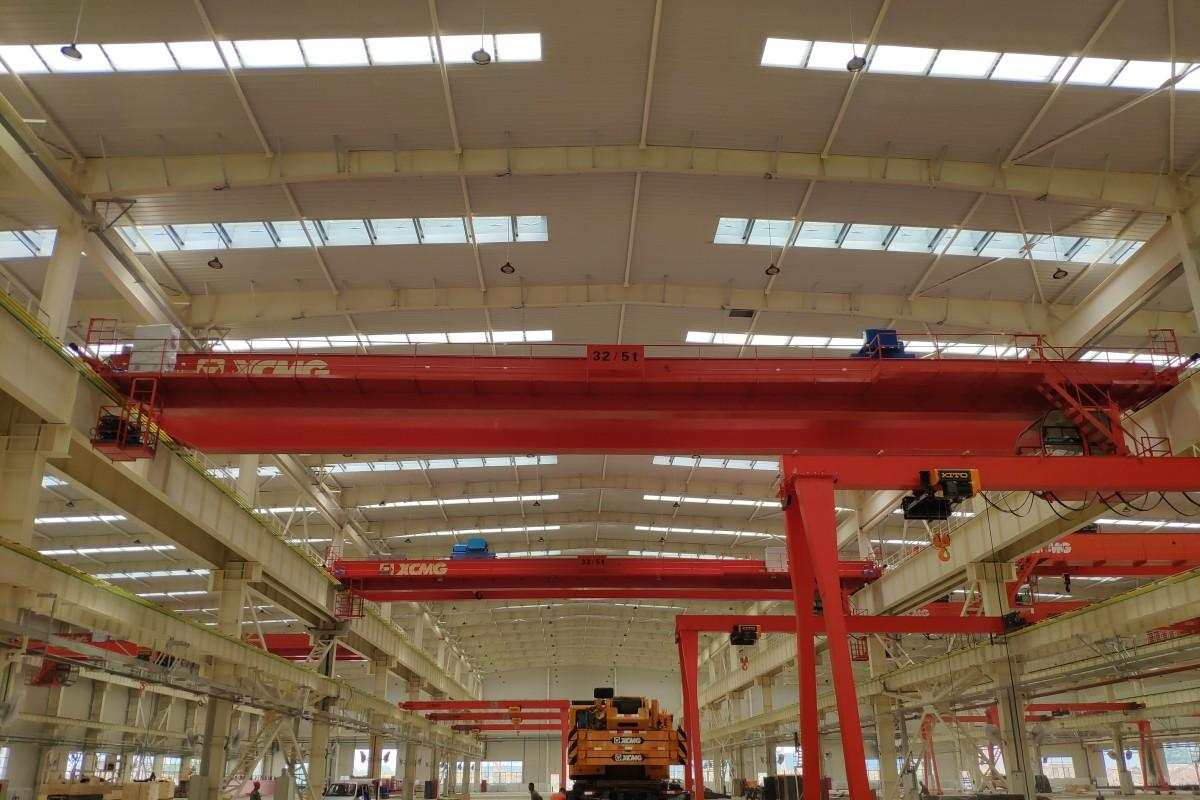

Реальные случаи

производственный процесс

Профессиональная команда НИОКР

Все инженеры прошли профессиональную подготовку в компании ABUS (Германия) и используют передовые инструменты 3D CAD и конечно-элементного анализа (FEA) для моделирования распределения напряжений и движения для каждой крановой системы.

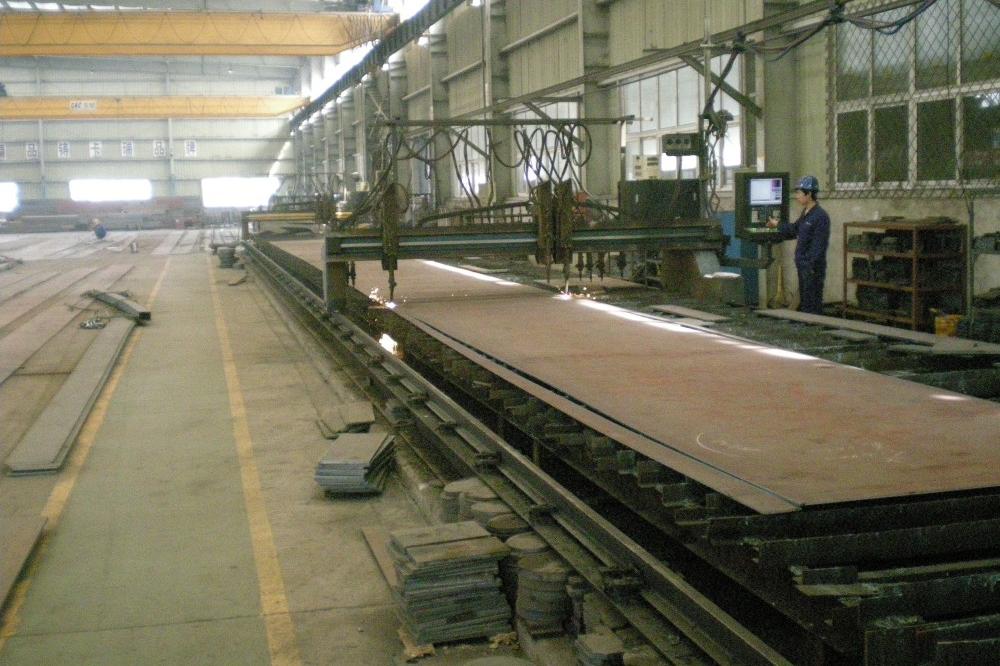

Система плазменной резки с ЧПУ

Автоматизированная резка всех компонентов нестандартной формы гарантирует высокую точность размеров и единообразие всего подъемного оборудования.

40-метровый станок для газовой резки с ЧПУ

Все листы стенки точно вырезаются за один проход с использованием ЧПУ, что обеспечивает точность изгиба. Ручная газовая резка не допускается — для нестандартных форм используются только ЧПУ или специализированный инструмент.

Гибочный станок с ЧПУ WEH 2500 мм 400T

Используется для детальной формовки небольших деталей крана, обеспечивая точную форму и превосходный внешний вид.

Горизонтально-расточной и фрезерный станок с ЧПУ

Благодаря 8-метровому ходу и полному микрокомпьютерному управлению обработка концевой балки выполняется за одну установку, что позволяет гарантировать строгую прямолинейность развал-схождения и другие критические допуски.

Вертикальные обрабатывающие центры серии VMC

Программируемые на станках с ЧПУ процессы гарантируют высокоточное изготовление деталей, гарантируя отличную точность сборки и общее качество продукции.

Полностью автоматическая дробеструйная линия длиной 60 м

После сварки каждая подкрановая балка проходит дробеструйную обработку. Этот процесс удаляет окисление, улучшает адгезию краски и устраняет остаточные напряжения, продлевая срок службы конструкции.

Окрасочная камера ZS

Все компоненты наших электрических канатных талей покрыты высокоэффективной полиуретановой краской, обеспечивающей долговечность и привлекательный внешний вид.

Испытательные стенды для подъемников и тележек

100% электрических талей и тележек подключаются к индивидуальному источнику питания и проходят индивидуальные испытания, чтобы гарантировать полную функциональность и соответствие требованиям перед отправкой с завода.

Платформа для полносистемного тестирования

Каждый нестандартный или вновь разработанный кран перед поставкой проходит комплексные эксплуатационные испытания на нашем специализированном комплексном испытательном стенде.

Свяжитесь с нами для получения расценок

Модернизируйте свои подъёмные операции с помощью решений KRC, разработанных в Германии. Свяжитесь с нами сегодня!