Китайско-германское сотрудничество

Европейские козловые и полукозловые краны KRC

Надежные краны грузоподъемностью до 320 тонн и пролетом 50 м, предназначенные для строительства метрополитена, складов под открытым небом и погрузочно-разгрузочных работ в цехах.

О фабрике KRC

Компания Karui Lifting Equipment Co., Ltd. (KRC), основанная в 1998 году, специализируется на интеллектуальных мостовых кранах европейского стандарта благодаря стратегическому партнерству с ABUS Group, ведущим немецким производителем кранов. KRC, имеющая сертификат класса А и более 20 запатентованных технологий, вносит свой вклад в развитие китайской промышленности. Руководство по проектированию кранов и национальным стандартам кранов. Наше производственное предприятие разработало крупнейший в отрасли двухбалочный мостовой кран (грузоподъёмность 360 тонн / пролёт 34,5 м), который используется в таких критически важных отраслях, как строительство метрополитена, промышленное складирование и точное производство.

- Максимальная грузоподъемность: 320 тонн

- Максимальный пролет: 50 м

- Конструкции, соответствующие FEM/ISO

- Сертификация A-Grade

- Энергоэффективное управление VFD

- 25% — более длительный срок службы по сравнению с обычными моделями

Европейские козловые и полукозловые краны

Европейские козловые и полукозловые краны KRC, работающие на технологии ABUS, обладают грузоподъемностью до 320 тонн и пролетом 50 м с оптимизированными для ANSYS коробчатыми балками для подъема тяжелых грузов.

Двухбалочный козловой кран

Ключевые преимущества

◼ Структурная целостность: Двухсварные балки с моделированием FEM 1.001

◼ Умное управление: Чувствительный к нагрузке частотно-регулируемый привод снижает потребление энергии на 35%

◼ Гибкость прикрепления: Электромагниты | Грейферы | Траверсы

Промышленные применения

◼ Обработка рулонов стали на прокатных станах

◼ Погрузка контейнеров на портовых терминалах

◼ Установка турбин на электростанциях

| Параметр | Спецификация |

|---|---|

| Емкость | До 320т |

| Охватывать | До 50 м |

| Скорость движения крана | 3-30м/мин |

| Скорость движения тележки | 4-40м/мин |

| Скорость подъема | 0,4-16 м/мин |

| Подъемные инструменты | Крюк, захват, электромагнитный |

| Контроль | Кабина, удаленная |

Однобалочные козловые краны

Эксплуатационные характеристики

◼ Профили скорости: Полностью регулируемый частотный привод

◼Рабочий цикл: Классификация FEM A3/A4

◼ Окружающая среда: Защита IP55 (пыле- и влагозащита)

Типичные варианты использования

◼ Обработка поддонов на складе

◼ Управление складом сборного железобетона

◼ Линии сборки автомобильных деталей

| Параметр | Спецификация |

|---|---|

| Емкость | До 20т |

| Охватывать | До 36м |

| Скорость движения крана | 3-30м/мин |

| Скорость движения тележки | 4-40м/мин |

| Скорость подъема | 0,4-16 м/мин |

| Подъемные инструменты | Крюк, захват, электромагнитный |

| Контроль | Кабина, удаленная |

Полукозловые краны

Технические параметры

◼ Высота подъема: До 20 м

◼ Системы управления: Беспроводной пульт дистанционного управления (радиус действия 100 м)

◼ Конструктивная толерантность: EN 1090-2 Класс EXC3

Отраслевые приложения

◼ Позиционирование инструментов в мастерских на аэрокосмических заводах

◼ Техобслуживающие отсеки в железнодорожных депо

◼ Подача прессовой линии в штамповочных цехах

| Параметр | Спецификация |

|---|---|

| Емкость | До 100т |

| Охватывать | До 30 м |

| Скорость движения крана | 3-30м/мин |

| Скорость движения тележки | 4-40м/мин |

| Скорость подъема | 0,4-16 м/мин |

| Подъемные инструменты | Крюк, захват, электромагнитный |

| Контроль | Кабина, удаленная |

Приложения

Козловые и полукозловые краны KRC обеспечивают точность в различных отраслях:

- Строительство метро: Двухбалочный портальный кран для перемещения тяжелых материалов.

- Открытые склады: Двухбалочный козловой кран для эффективной загрузки.

- Железные дороги: Однобалочный козловой кран для экономичной разгрузки.

- Мастер-классы: Полукозловые краны для гибкой транспортировки материалов.

- Производство: Полукозловой кран для задач с большими пролетами.

Реальные случаи

производственный процесс

Профессиональная команда НИОКР

Все инженеры прошли профессиональную подготовку в компании ABUS (Германия) и используют передовые инструменты 3D CAD и конечно-элементного анализа (FEA) для моделирования распределения напряжений и движения для каждой крановой системы.

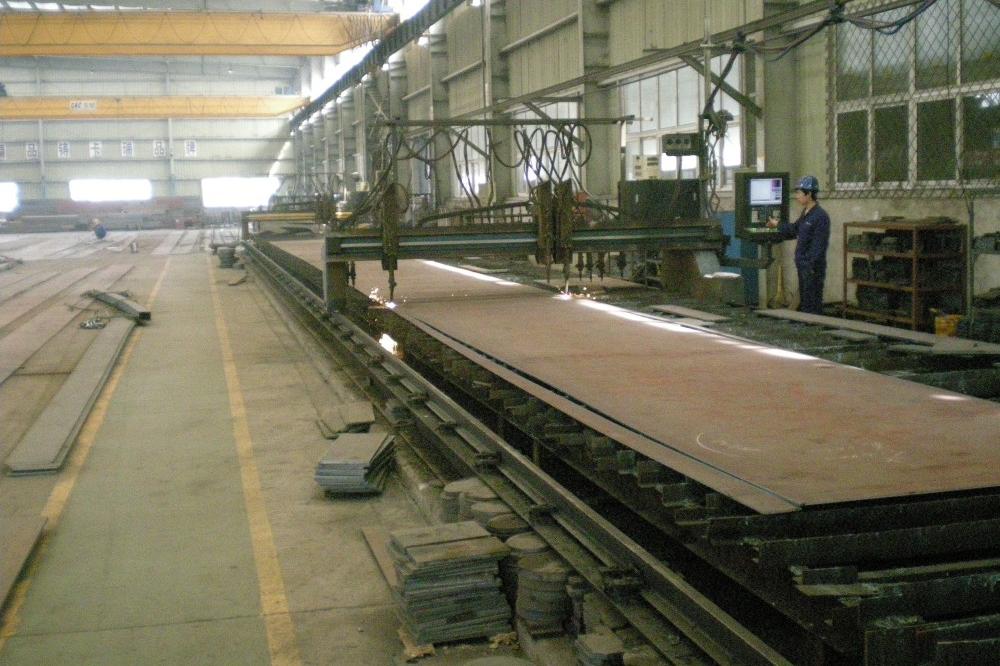

Система плазменной резки с ЧПУ

Автоматизированная резка всех компонентов нестандартной формы гарантирует высокую точность размеров и единообразие всего подъемного оборудования.

40-метровый станок для газовой резки с ЧПУ

Все листы стенки точно вырезаются за один проход с использованием ЧПУ, что обеспечивает точность изгиба. Ручная газовая резка не допускается — для нестандартных форм используются только ЧПУ или специализированный инструмент.

Гибочный станок с ЧПУ WEH 2500 мм 400T

Используется для детальной формовки небольших деталей крана, обеспечивая точную форму и превосходный внешний вид.

Горизонтально-расточной и фрезерный станок с ЧПУ

Благодаря 8-метровому ходу и полному микрокомпьютерному управлению обработка концевой балки выполняется за одну установку, что позволяет гарантировать строгую прямолинейность развал-схождения и другие критические допуски.

Вертикальные обрабатывающие центры серии VMC

Программируемые на станках с ЧПУ процессы гарантируют высокоточное изготовление деталей, гарантируя отличную точность сборки и общее качество продукции.

Полностью автоматическая дробеструйная линия длиной 60 м

После сварки каждая подкрановая балка проходит дробеструйную обработку. Этот процесс удаляет окисление, улучшает адгезию краски и устраняет остаточные напряжения, продлевая срок службы конструкции.

Окрасочная камера ZS

Все компоненты наших электрических канатных талей покрыты высокоэффективной полиуретановой краской, обеспечивающей долговечность и привлекательный внешний вид.

Испытательные стенды для подъемников и тележек

100% электрических талей и тележек подключаются к индивидуальному источнику питания и проходят индивидуальные испытания, чтобы гарантировать полную функциональность и соответствие требованиям перед отправкой с завода.

Платформа для полносистемного тестирования

Каждый нестандартный или вновь разработанный кран перед поставкой проходит комплексные эксплуатационные испытания на нашем специализированном комплексном испытательном стенде.

Свяжитесь с нами для получения расценок

Модернизируйте свои подъёмные операции с помощью решений KRC, разработанных в Германии. Свяжитесь с нами сегодня!