Китайско-германское сотрудничество

Продукция KRC Crane

Откройте для себя наши инновационные решения в области подъема тяжелой техники для отраслей по всему миру, созданные на основе китайско-немецкого опыта.

Однобалочный мостовой кран европейского типа

Этот легкий и эффективный кран грузоподъемностью до 20 тонн и пролетом 7–35 м идеально подходит для производственных и складских помещений, обеспечивая точное управление и минимальные затраты на техническое обслуживание.

Двухбалочный мостовой кран европейского типа

Прочный кран грузоподъемностью до 360 тонн и пролетом 34,5 м, предназначенный для подъема тяжелых грузов в металлургической и сталелитейной промышленности, отличающийся превосходной устойчивостью.

Европейский подвесной кран

Компактное подвесное решение, подвешиваемое к потолку, идеально подходит для эффективной транспортировки материалов в ограниченных производственных помещениях.

Умный кран

Автоматизированный интеллектуальный кран грузоподъемностью до 100 тонн и пролетом 36 м, оснащенный лазерной навигацией и разработанной в университете логикой управления для химической, металлургической и складской промышленности.

Стреловые краны

Консольные краны KRC, спроектированные с применением технологии ABUS, обеспечивают точный подъем груза весом от 80 до 6300 кг. Они обеспечивают поворот на 180°–360° для производственной, складской и химической промышленности, а для обеспечения безопасности поставляются с опциональными взрывозащищенными подъемниками STAHL.

Легкая крановая система KBK

Легкие крановые системы KRC-KBK: модульные жесткие и гибкие рельсы (грузоподъемность 2000 кг, пролет 10 м).

Козловые краны

Компания KRC Precision Engineering разработала три передовых решения для козловых кранов: двухбалочные (320 т/50 м), однобалочные (32 т/30 м) и полукозловые системы с оптимизированными для ANSYS коробчатыми балками и сертифицированной по ISO конструкцией. Благодаря частотно-регулируемому приводу и возможности установки различных видов навесного оборудования (крюки, электромагниты, грейферы) наши краны используются в метростроении, портовой логистике и промышленных цехах.

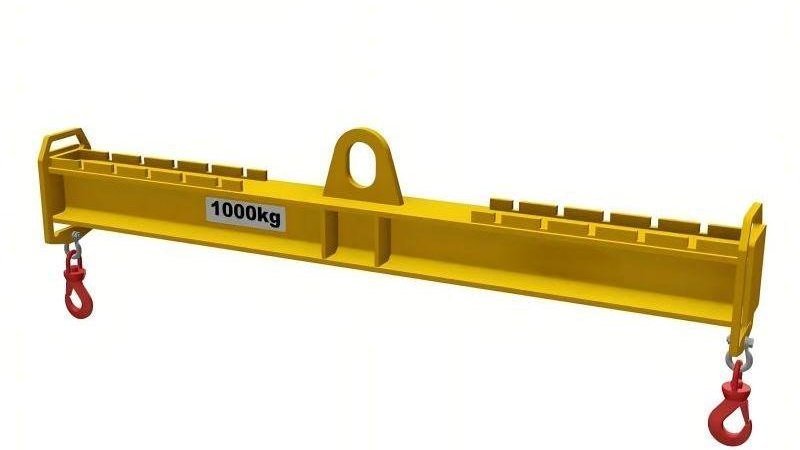

Распределительные балки

Компания KRC предлагает широкий ассортимент траверс, разработанных для обеспечения безопасного и эффективного распределения веса крупногабаритных или тяжёлых грузов. Благодаря различным вариантам грузоподъёмности, рабочей ширины, диапазонов регулировки и типов крюков, наши траверсы подходят для широкого спектра промышленных применений.

производственный процесс

Профессиональная команда НИОКР

Все инженеры прошли профессиональную подготовку в компании ABUS (Германия) и используют передовые инструменты 3D CAD и конечно-элементного анализа (FEA) для моделирования распределения напряжений и движения для каждой крановой системы.

Система плазменной резки с ЧПУ

Автоматизированная резка всех компонентов нестандартной формы гарантирует высокую точность размеров и единообразие всего подъемного оборудования.

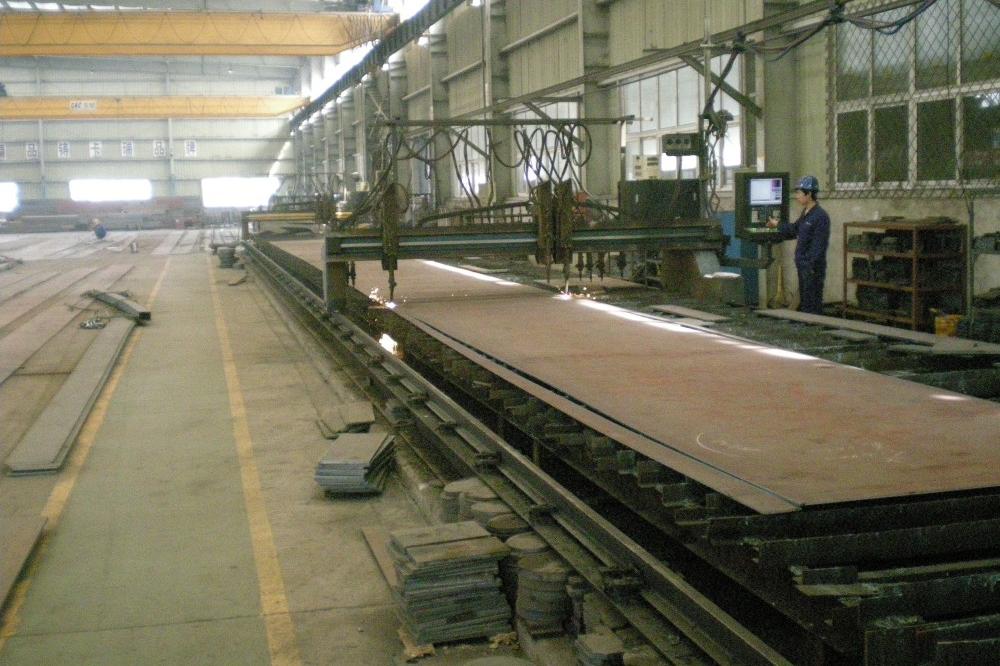

40-метровый станок для газовой резки с ЧПУ

Все листы стенки точно вырезаются за один проход с использованием ЧПУ, что обеспечивает точность изгиба. Ручная газовая резка не допускается — для нестандартных форм используются только ЧПУ или специализированный инструмент.

Гибочный станок с ЧПУ WEH 2500 мм 400T

Используется для детальной формовки небольших деталей крана, обеспечивая точную форму и превосходный внешний вид.

Горизонтально-расточной и фрезерный станок с ЧПУ

Благодаря 8-метровому ходу и полному микрокомпьютерному управлению обработка концевой балки выполняется за одну установку, что позволяет гарантировать строгую прямолинейность развал-схождения и другие критические допуски.

Вертикальные обрабатывающие центры серии VMC

Программируемые на станках с ЧПУ процессы гарантируют высокоточное изготовление деталей, гарантируя отличную точность сборки и общее качество продукции.

Полностью автоматическая дробеструйная линия длиной 60 м

После сварки каждая подкрановая балка проходит дробеструйную обработку. Этот процесс удаляет окисление, улучшает адгезию краски и устраняет остаточные напряжения, продлевая срок службы конструкции.

Окрасочная камера ZS

Все компоненты наших электрических канатных талей покрыты высокоэффективной полиуретановой краской, обеспечивающей долговечность и привлекательный внешний вид.

Испытательные стенды для подъемников и тележек

100% электрических талей и тележек подключаются к индивидуальному источнику питания и проходят индивидуальные испытания, чтобы гарантировать полную функциональность и соответствие требованиям перед отправкой с завода.

Платформа для полносистемного тестирования

Каждый нестандартный или вновь разработанный кран перед поставкой проходит комплексные эксплуатационные испытания на нашем специализированном комплексном испытательном стенде.

Свяжитесь с нами для получения расценок

Модернизируйте свои подъёмные операции с помощью решений KRC, разработанных в Германии. Свяжитесь с нами сегодня!