Особенность

Rugged Durability

All-steel compact construction, lightweight & corrosion-resistant.

Grade 80 calibrated load chain + stainless steel options (1T/2T models).

Drain holes prevent water buildup; enclosed multi-disc brakes.

Safety Compliance

ATEX Zone 2 certified (Zone 1 kit optional) for explosive environments.

CE certification with overload protection & emergency air shut-off.

Fail-safe brakes + upper/lower limit switches.

High Performance

Precision variable speed control for critical spotting.

Gear-type air motor: minimal parts, near-zero maintenance.

-20°C operational capability (cold-weather kit optional).

Ball-bearing bottom hook for smooth rotation under load.

Versatile Configurations

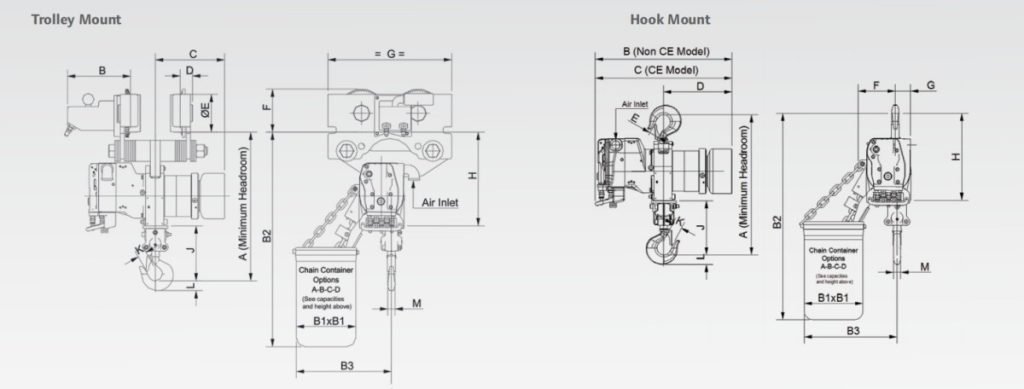

Hook-mount or trolley options (plain/geared/motorized).

Cast iron pendant controls for extended service life.

Описание продукта

Engineered for extreme duty cycles and harsh industrial operations, the Ingersoll Rand Liftchain® Air Hoist excels where electrical power is impractical or hazardous. Its modular ATEX-certified design—available through authorized distributor KRC—ensures reliable performance in oil rigs, mining, FLNG vessels, and explosive (Zone 2/1) environments.

The hoist’s air-driven system eliminates spark risks while delivering high-speed lifting with precision variable control. Critical safety features include CE-certified overload protection, fail-safe brakes, and integrated limit switches. Encased multi-disc brakes and drainage technology combat corrosion, while stainless steel chain options extend longevity in humid or chemical-exposed settings.

As your Ingersoll Rand partner, KRC provides certified hoists tailored for high-risk sectors, backed by technical expertise and lifecycle support. Optimize productivity with minimal downtime: the Liftchain®’s near-maintenance-free operation and industrial-grade durability deliver unmatched total cost of ownership.

| Модель | Тип | Lifting Capacity (Metric Tons) | Reeves of Chain | Headroom (mm (in)) | Trolley Flange Adjustment Range (mm (in)) | Hoist Weight with 3m (10ft) of chain (kg (lb)) | Trolley Weight(1) (kg (lb)) | Weight per additional meter of lift (kg (lb)) |

|---|---|---|---|---|---|---|---|---|

| LC2A015SI | Крюк | 1.5 | 1 | 409 (16.1) | – | 38 (84) | – | 1.5 (3.3) |

| LC2A030DI | Крюк | 3 | 2 | 549 (21.6) | – | 48 (106) | – | 3.0 (6.6) |

| LC2A040SI | Крюк | 4 | 1 | 580 (22.8) | – | 90 (198) | – | 3.8 (8.4) |

| LC2A060QI | Крюк | 6 | 4 | 653 (25.7) | – | 74 (163) | – | 6.0 (13.2) |

| LC2A060SI | Крюк | 6 | 1 | 717 (28.2) | – | 125 (276) | – | 5.7 (12.6) |

| LC2A080DI | Крюк | 8 | 2 | 807 (31.8) | – | 118 (260) | – | 7.6 (16.8) |

| LC2A120DI | Крюк | 12 | 2 | 945 (37.2) | – | 170 (375) | – | 11.4 (25.1) |

| LC2A125SI | Крюк | 12.5 | 1 | 865 (34.1) | – | 395 (871) | – | 10.7 (23.6) |

| LC2A180TI | Крюк | 18 | 3 | 1,063 (41.9) | – | 277 (611) | – | 17.1 (37.7) |

| LC2A250QI | Крюк | 25 | 4 | 1,156 (45.5) | – | 324 (714) | – | 23.0 (50.7) |

| LC2A250DI | Крюк | 25 | 2 | 1,235 (48.6) | – | 558 (1,230) | – | 21.4 (47.2) |

| LC2A375TI | Крюк | 37.5 | 3 | 1,484 (58.4) | – | 855 (1,885) | – | 32.1 (70.8) |

| LC2A500QI | Крюк | 50 | 4 | 1,590 (62.6) | – | 965 (2,127) | – | 42.8 (94.4) |

| LCA750TI | Крюк | 75 | 3 | 2,338 (92.0) | – | 1,700 (3,748) | – | 73.5 (162.0) |

| LCA1000QI | Крюк | 100 | 4 | 2,455 (96.7) | – | 2,200 (4,850) | – | 98.0 (216.1) |

| LC2A015SI | Trolley | 1.5 | 1 | 480 (18.9) | 80-200 (3.2-7.9) | 38 (84) | 57 (126) | 1.5 (3.3) |

| LC2A030DI | Trolley | 3 | 2 | 592 (23.3) | 80-200 (3.2-7.9) | 48 (106) | 55 (121) | 3.0 (6.6) |

| LC2A040SI | Trolley | 4 | 1 | 590 (23.2) | 80-200 (3.2-7.9) | 90 (198) | 55 (121) | 3.8 (8.4) |

| LC2A060QI | Trolley | 6 | 4 | 702 (27.6) | 100-310 (3.9-12.2) | 74 (163) | 143 (315) | 6.0 (13.2) |

| LC2A060SI | Trolley | 6 | 1 | 730 (28.7) | 100-310 (3.9-12.2) | 125 (276) | 142 (313) | 5.7 (12.6) |

| LC2A080DI | Trolley | 8 | 2 | 815 (32.1) | 100-310 (3.9-12.2) | 118 (260) | 142 (313) | 7.6 (16.8) |

| LC2A120DI | Trolley | 12 | 2 | 995 (39.2) | 130-310 (5.1-12.2) | 170 (375) | 182 (401) | 11.4 (25.1) |

| LC2A125SI | Trolley | 12.5 | 1 | 1,000 (39.4) | 160-310 (6.3-12.2) | 395 (871) | 175 (386) | 10.7 (23.6) |

| LC2A180TI | Trolley | 18 | 3 | 1,195 (47.1) | 140-310 (5.5-12.2) | 277 (611) | 375 (826) | 17.1 (37.7) |

| LC2A250QI | Trolley | 25 | 4 | 1,240 (48.8) | 140-310 (5.5-12.2) | 324 (714) | 376 (829) | 23.0 (50.7) |

| LC2A250DI | Trolley | 25 | 2 | 990 (39.0) | 160-310 (6.3-12.2) | 558 (1,230) | 377 (831) | 21.4 (47.2) |

| LC2A375TI | Trolley | 37.5 | 3 | 1,134 (44.6) | 160-310 (6.3-12.2) | 855 (1,885) | 730 (1,609) | 32.1 (70.8) |

| LC2A500QI | Trolley | 50 | 4 | 1,182 (46.5) | 160-310 (6.3-12.2) | 965 (2,127) | 770 (1,698) | 42.8 (94.4) |

| LCA750TI | Trolley | 75 | 3 | 1,845 (72.6) | 160-310 (6.3-12.2) | 1,700 (3,748) | 2,800 (6,172) | 73.5 (162.0) |

| LCA1000QI | Trolley | 100 | 4 | 1,901 (74.8) | 160-310 (6.3-12.2) | 2,200 (4,850) | 2,500 (5,512) | 98.0 (216.1) |

| LC2A015SIL | Low Profile | 1.5 | 1 | 275 (10.8) | 81-310 (3.2-12.2) | 38 (84) | 82 (126) | 1.5 (3.3) |

| LC2A030DIL | Low Profile | 3 | 2 | 386 (15.2) | 81-310 (3.2-12.2) | 48 (106) | 82 (121) | 3 (6.6) |

| LC2A060QIL | Low Profile | 6 | 4 | 465 (18.3) | 120-310 (4.7-12.2) | 74 (163) | 176 (315) | 6 (13.2) |

| LC2A060SIL | Low Profile | 6 | 1 | 475 (18.7) | 140-310 (5.5-12.2) | 125 (276) | 375 (313) | 5.7 (12.6) |

| LC2A080DIL | Low Profile | 8 | 2 | 590 (23.2) | 120-310 (4.7-12.2) | 118 (260) | 182 (313) | 7.6 (16.8) |

| LC2A120DIL | Low Profile | 12 | 2 | 670 (26.4) | 140-310 (5.5-12.2) | 170 (375) | 370 (401) | 11.4 (25.1) |

| LC2A180TIL | Low Profile | 18 | 3 | 730 (28.7) | 210-310 (8.3-12.2) | 277 (611) | 413 (826) | 17.1 (37.7) |

| LC2A250QIL | Low Profile | 25 | 4 | 775 (30.5) | 160-310 (6.3-12.2) | 324 (714) | 416 (829) | 23 (50.7) |