Wenn man die Fähigkeiten einer Winde betrachtet, muss man ihre Tragfähigkeit ist von größter Bedeutung. Eine Winde ist ein vielseitiges Werkzeug, das in verschiedenen Branchen eingesetzt wird, vom Baugewerbe bis hin zur Forstwirtschaft und Freizeitaktivitäten. In diesem Artikel untersuchen wir, wie viel eine Winde heben kann, welche Faktoren ihre Leistung beeinflussen und wie Sie die richtige Winde für Ihre spezifischen Anforderungen auswählen.

Was ist eine Winde und wozu dient sie?

A Winde ist ein mechanisches Gerät zum Auf- oder Abwickeln eines Kabels, Seils oder einer Kette. Dies ermöglicht dem Benutzer, schwere Lasten präzise und kontrolliert zu ziehen, anzuheben oder zu sichern. Winden werden häufig für Anwendungen wie die folgenden verwendet:

- Fahrzeugbergung

- Bau- und Pfahlgründungsprojekte

- Protokollierungsvorgänge

- Heben auf See und im Offshore-Bereich

- Freizeitaktivitäten wie Offroadfahren

Winden unterscheiden sich in Kapazität, Betriebsart (manuell, elektrisch, hydraulisch oder pneumatisch) und Design, sodass sie sowohl für leichte als auch für schwere Aufgaben geeignet sind.

Wichtige Faktoren, die die Tragfähigkeit einer Winde beeinflussen

1. Leistung des Windenmotors

Die Leistung eines Windenmotors ist direkt proportional zu seiner Hubkapazität. Winden mit Motoren höherer Leistung können mehr Kraft erzeugen und somit schwerere Lasten heben. Zum Beispiel:

- Elektrische Winden: Ideal für das Heben leichterer und mittelschwerer Lasten mit Kapazitäten von 500 bis 30.000 Pfund.

- Hydraulische Winden: Für Schwerlastaufgaben konzipiert, die oft eine Tragfähigkeit von über 50.000 Pfund aufweisen.

2. Übersetzungsverhältnis

Das Übersetzungsverhältnis bestimmt, wie viel Leistung die Winde in Zugkraft umwandeln kann. Niedrigere Übersetzungsverhältnisse bieten eine höhere Zugkapazität, können aber die Geschwindigkeit verringern, sodass sie für schwere Lasten geeignet sind.

3. Drahtseil- oder Kabelstärke

Material, Durchmesser und Länge des Seils beeinflussen maßgeblich die Leistungsfähigkeit der Winde. Stahlseile sind langlebig und stark und daher für den industriellen Einsatz geeignet, während synthetische Seile Flexibilität bieten und leicht für den Freizeitgebrauch sind.

4. Lastwinkel

Winden arbeiten am effizientesten, wenn die Last geradlinig gezogen oder angehoben wird. Winkelzüge führen zu zusätzlicher Belastung, was die effektive Hubkapazität verringern kann.

5. Trommelgröße und -konfiguration

Die Größe der Trommel beeinflusst, wie viel Seil aufgewickelt werden kann und welche Zugkraft effektiv ist. Eine volle Trommel verringert das Drehmoment der Winde und verringert so ihre Hubleistung.

Berechnung der Windenkapazität für Hebeaufgaben

Um zu bestimmen, wie viel eine Winde heben kann, müssen Sie sowohl die zulässiges Gesamtgewicht und die Sicherheitsfaktor. Eine allgemeine Faustregel für das Winden ist, eine Kapazität von mindestens 1,5 bis 2 mal das Gewicht der Ladung. Zum Beispiel:

- Für eine Last von 10.000 Pfund benötigen Sie eine Winde mit einer Mindestkapazität von 15.000 Pfund.

- Hinzufügen eines Umlenkrolle kann die Zugkraft der Winde effektiv verdoppeln.

Windentypen und ihre Hubkapazitäten

1. Manuelle Winden

- Kapazität: Bis zu 1 Tonne

- Am besten für: Leichte Hebeaufgaben, wie das Anheben kleiner Lasten in Werkstätten.

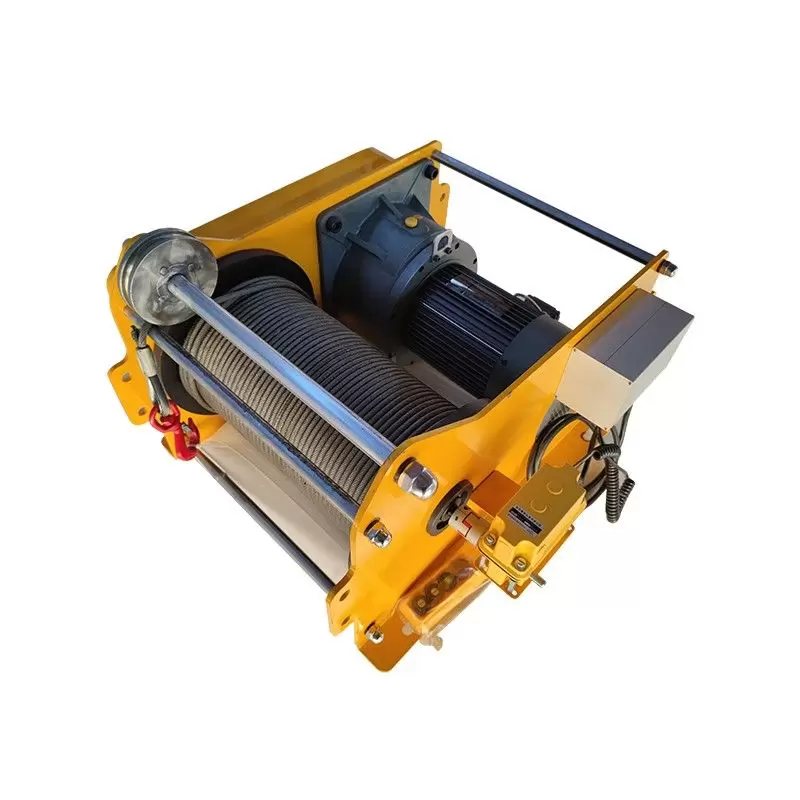

2. Elektrische Winden

- Kapazität: 0,5 bis 30 Tonnen

- Am besten für: Häufiger Einsatz in Umgebungen mit Zugang zu Elektrizität, wie Baustellen und Industrielagern.

3. Hydraulische Winden

- Kapazität: 5 bis 100+ Tonnen

- Am besten für: Hochleistungsanwendungen, die Dauerbetrieb erfordern, wie z. B. die Schifffahrts- und Forstindustrie.

4. Pneumatische Winden

- Kapazität: 1 bis 20 Tonnen

- Am besten für: Gefährliche Umgebungen, in denen die Gefahr elektrischer Funken besteht, wie z. B. Ölplattformen.

5. Spezialwinden

- Rückewinden: Konzipiert für das Heben von Baumstämmen mit Zugkapazitäten von 2 bis 20 Tonnen.

- Traktionswinden: Konstruiert für den Seilbahnbetrieb mit einer Tragfähigkeit von bis zu 15 Tonnen oder mehr.

Sicherheitsaspekte beim Windenbetrieb

Der Betrieb einer Winde erfordert die strikte Einhaltung von Sicherheitsprotokollen, um Unfälle oder Geräteausfälle zu vermeiden. Zu den wichtigsten Vorsichtsmaßnahmen gehören:

- Regelmäßige Inspektion: Überprüfen Sie Seil, Motor und Getriebe auf Verschleiß.

- Verwenden Sie das richtige Zubehör: Stellen Sie sicher, dass die Ladung mit geeigneten Schäkeln, Haken und Gurten gesichert ist.

- Überlastung vermeiden: Überschreiten Sie niemals die vom Hersteller angegebene Hubkapazität.

- Sicherheitsfunktionen aktivieren: Verwenden Sie Bremsen, Begrenzer und Überlastschutzmechanismen, sofern verfügbar.

So wählen Sie die richtige Winde aus

1. Definieren Sie Ihre Anforderungen

- Was ist die maximale Last, die Sie heben oder ziehen können?

- Wird die Winde für industrielle, Freizeit- oder gelegentliche Zwecke verwendet?

2. Passen Sie die Kapazität an die Anwendung an

Wählen Sie eine Winde mit einer Nennkapazität, die Ihre typische Last übersteigt. Für industrielle Aufgaben sollten Sie Hochleistungswinden mit erweiterten Sicherheitsfunktionen in Betracht ziehen.

3. Stromquelle bewerten

Wählen Sie je nach Umgebung und Nutzungshäufigkeit zwischen elektrisch, hydraulisch oder pneumatisch.

4. Marke und Garantie prüfen

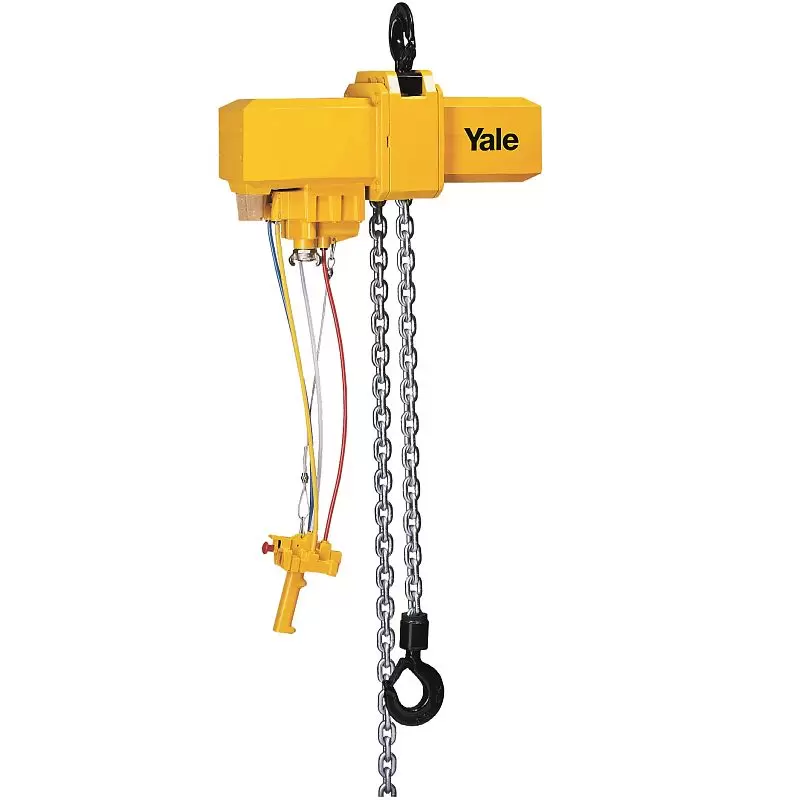

Renommierte Marken wie Yale, ABUSund andere Hersteller von Industrieprodukten bieten zuverlässige Produkte mit Garantie an.

Top-Windenmodelle und ihre Funktionen

Hier einige Beispiele für leistungsstarke, auf spezielle Anforderungen zugeschnittene Winden:

Yale CPA Drucklufthebezeug mit Laufkatze: Kombiniert pneumatische Kraft mit Mobilität, ideal für industrielles Heben.

JKL Schnelle Rammwinde für den Bau: Optimiert für den Einsatz im Bauwesen, mit Traglasten bis zu 10 Tonnen.

Elektrische vertikale Hebewinde für Kunstlichter: Leise und präzise, perfekt für architektonische Lichtinstallationen.

Abschluss

Die Hubkapazität einer Winde hängt von mehreren Faktoren ab, darunter Motorleistung, Seilstärke und Getriebekonfiguration. Wenn Sie diese Aspekte verstehen und die richtige Winde für Ihre Anforderungen auswählen, können Sie einen sicheren und effizienten Betrieb bei unterschiedlichsten Anwendungen gewährleisten. Stellen Sie die Sicherheit immer an erste Stelle und konsultieren Sie Experten, wenn Sie die ideale Ausrüstung für Ihre Aufgaben auswählen.