Deutsch-Chinesische Zusammenarbeit

KRC-Auslegerkrane

Vielseitige Säulen- und Wandschwenkkrane für präzisen und effizienten Materialumschlag.

Über KRC Factory

Karui Lifting Equipment Co., Ltd. (KRC) wurde 1998 in Luoyang gegründet und ist ein Pionier für europäische und intelligente Krane. Das Unternehmen basiert auf der technischen Zusammenarbeit mit ABUS, Deutschlands führendem Kranhersteller. Als regionaler Vertreter von CMCO (USA) und DOLECO (Deutschland) ist KRC führend in der Krankonstruktion, -herstellung, -installation und -wartung. Mit 28 patentierten Technologien trägt KRC zum *Crane Design Manual* und den chinesischen Kranstandards bei. Unser Werk verfügt über höchste A-Klasse-Qualifikationen und hat einen rekordverdächtigen 360-Tonnen-Zweiträgerkran mit 34,5 m Spannweite produziert, der Branchen wie die Chemie-, Metallurgie- und Eisenbahnindustrie mit maßgeschneiderten Lösungen für Tausende von Unternehmen beliefert.

- Deutsch-chinesische Innovation: Partnerschaft mit ABUS für modernste Krantechnologie.

- Branchenführerschaft: Erster in China für intelligente Kräne im europäischen Stil.

- Bewährte Exzellenz: Henans „kleiner Riese“ und provinzielles F&E-Zentrum.

Unsere Schwenkkrane

Die mit ABUS-Technologie entwickelten Schwenkkrane von KRC bieten flexible Lösungen mit Tragfähigkeiten von 80 bis 4300 kg und sind ideal für kompakte Arbeitsbereiche.

Säulenschwenkkran LS

Mit 270° Schwenkbereich und einer Tragfähigkeit von 80–1000 kg ist dieser leichte Kran perfekt für die Fertigung geeignet und verfügt über einen elektrischen ABUS-Hebezeug und optional ein explosionsgeschütztes STAHL-Hebezeug für mehr Sicherheit.

| Auslegerlänge (m) | Tragkraft (kg) |

|---|---|

| Bis zu 7 | 80-250 |

| Bis zu 6 | 500 |

| Bis zu 5 | 1000 |

Säulenschwenkkran LW

Dieser ergonomische Kran bietet eine Schwenkbarkeit von 180° und eine Tragfähigkeit von 80–1000 kg und eignet sich mit seiner leichtgängigen Laufkatze und dem optionalen explosionsgeschützten Hebezeug von STAHL für einen sicheren Betrieb für die Lagerhaltung.

| Auslegerlänge (m) | Tragkraft (kg) |

|---|---|

| Bis zu 7 | 80-250 |

| Bis zu 6 | 500 |

| Bis zu 5 | 1000 |

Säulenschwenkkran LSX

Mit zusätzlicher Hubhöhe und einer Tragfähigkeit von 125–500 kg ist dieser Kran perfekt für die Fertigung geeignet und verfügt über einen niedrig gebauten Ausleger und ein optionales explosionsgeschütztes Hebezeug von STAHL.

| Auslegerlänge (m) | Tragkraft (kg) |

|---|---|

| Bis zu 7 | 125 |

| Bis zu 6 | 250 |

| Bis zu 4 | 500 |

Säulenschwenkkran VS

Dieser Kran ist ein Allrounder mit einer Tragfähigkeit von 125–4000 kg und eignet sich für Schwerlastaufgaben. Zur Sicherheit sind Schleifringe und ein optionaler explosionsgeschützter STAHL-Hebezeug vorhanden.

| Auslegerlänge (m) | Tragkraft (kg) |

|---|---|

| Bis zu 10 | 125-2500 |

| Bis zu 9 | 3200 |

| Bis zu 8 | 4000 |

Wandschwenkkran LWX

Dieser Wandkran ist ideal für die Montage mit einer Tragfähigkeit von 125–500 kg und nutzt den Platz optimal aus. Er verfügt über einen niedrig gebauten Ausleger und ein optionales explosionsgeschütztes Hebezeug von STAHL.

| Auslegerlänge (m) | Tragkraft (kg) |

|---|---|

| Bis zu 7 | 125 |

| Bis zu 6 | 250 |

| Bis zu 4 | 500 |

Wandschwenkkran VW

Hält Böden frei mit einer Kapazität von 125–4000 kg, ideal für die chemische Industrie, mit einem robusten Ausleger und einem optionalen explosionsgeschützten Hebezeug von STAHL für mehr Sicherheit.

| Auslegerlänge (m) | Tragkraft (kg) |

|---|---|

| Bis zu 10 | 125-2500 |

| Bis zu 9 | 3200 |

| Bis zu 8 | 4000 |

Hebevorrichtungen

KRC bietet eine Reihe von Hebevorrichtungen an, die mit unseren Schwenkkranen kompatibel sind und für vielfältige industrielle Anwendungen mit Präzision und Sicherheit konzipiert sind.

Elektrische Kettenzüge (80 kg–4 Tonnen) ermöglichen zuverlässiges Heben in der Fertigung und Lagerhaltung und gewährleisten einen reibungslosen Betrieb mit KRC-Auslegerkranen.

Kostengünstige manuelle Hebezeuge (bis zu 2 Tonnen) sind ideal für kleine Werkstätten und bieten robustes Heben bei minimalem Wartungsaufwand für KRC-Auslegerkräne.

Explosionsgeschützte Hebezeuge von STAHL (bis zu 8 Tonnen) gewährleisten sicheres Heben in gefährlichen Umgebungen wie Chemiewerken und sind mit allen KRC-Auslegerkranen kompatibel.

Anwendungen

KRC-Auslegerkrane bieten Präzision und Flexibilität in allen Branchen:

- Herstellung: Präzises Handling für Montagelinien und Werkstätten.

- Lagerung: Effiziente Materialbewegung in kompakten Lagerbereichen.

- Chemische Industrie: Sicheres Heben mit optionalem explosionsgeschütztem Hebezeug von STAHL für explosionsgefährdete Umgebungen.

- Automobilindustrie: Zuverlässiges Bauteilhandling in Produktionsanlagen.

- Konstruktion: Vielseitige Lösungen für kleine Hebeaufgaben.

Erfolgsprojekte

KRC hat Auslegerkräne an führende Unternehmen geliefert und damit unser Know-how unter Beweis gestellt:

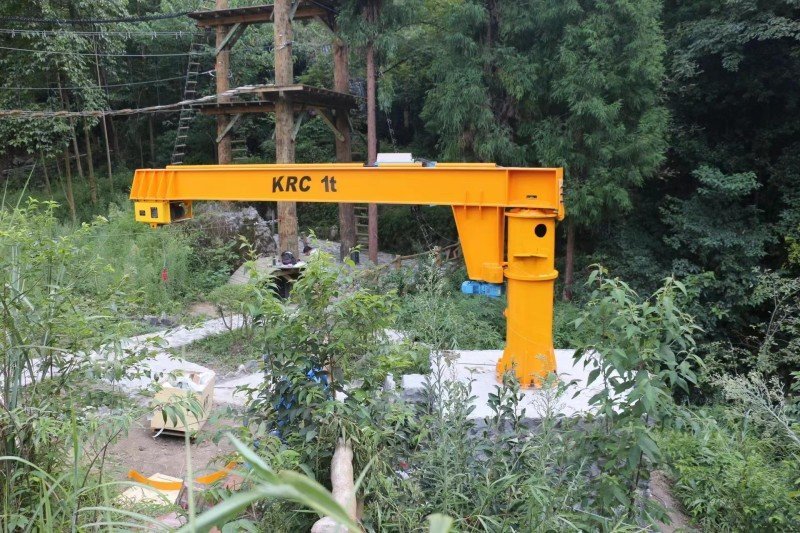

- Fanfan Co.: 1-Säulen-Schwenkkran LS für die Fertigung (2018).

- Xinxing-Rohre aus duktilem Eisen: 4-Wandschwenkkran LWX für die Lagerhaltung (2019).

- Petrochemische Unternehmen: 3,2-t-Auslegerkrane mit explosionsgeschützten Hebezeugen von STAHL (2020–2021).

Aktuelle Fälle

Produktionsprozess

Professionelles F&E-Team

Alle Ingenieure sind von ABUS (Deutschland) professionell geschult und nutzen fortschrittliche 3D-CAD- und Finite-Elemente-Analyse-Tools (FEA), um die Spannungsverteilung und Bewegung für jedes Kransystem zu simulieren.

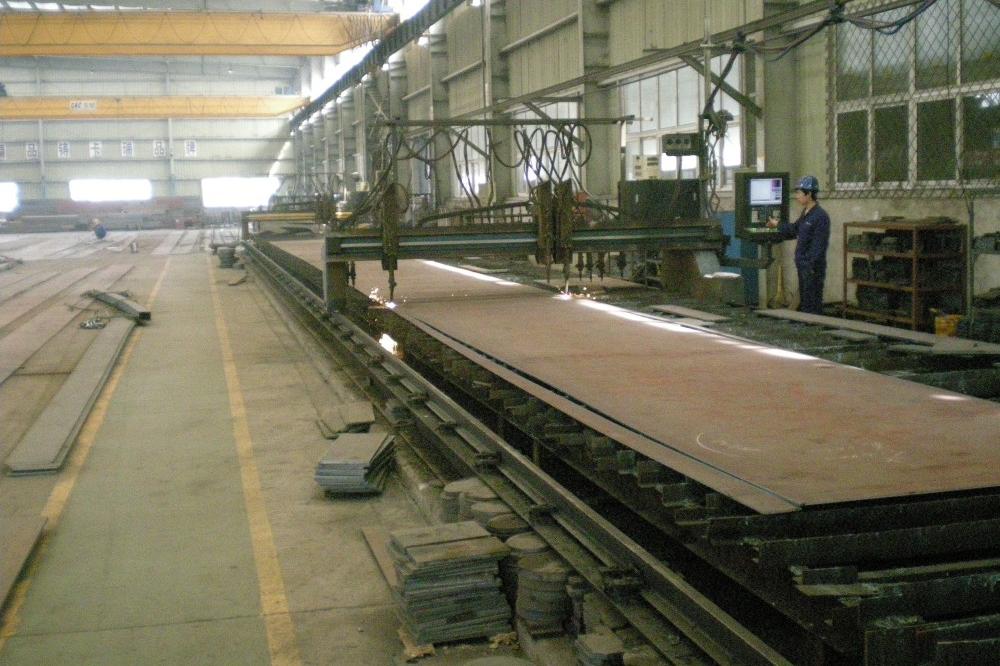

CNC-Plasmaschneidsystem

Das automatisierte Schneiden aller kundenspezifisch geformten Komponenten garantiert eine hohe Maßgenauigkeit und Konsistenz bei allen Hebegeräten.

40 m CNC-Brennschneidmaschine

Alle Stegplatten werden in einem einzigen Durchgang mithilfe von CNC-Technologie präzise geschnitten, um genaue Wölbungen zu gewährleisten. Manuelles Brennschneiden ist nicht zulässig. Für unregelmäßige Formen werden ausschließlich CNC- oder Spezialwerkzeuge verwendet.

2500 mm 400T WEH CNC-Biegemaschine

Wird für die detaillierte Formgebung kleiner Krankomponenten verwendet und gewährleistet eine präzise Formgebung und ein erstklassiges Enderscheinungsbild.

CNC-Horizontalbohr- und Fräsmaschine

Mit einem Verfahrweg von 8 Metern und vollständiger Mikrocomputersteuerung wird die Endträgerbearbeitung in einem einzigen Arbeitsgang abgeschlossen, um die strikte Geradlinigkeit der Radausrichtung und andere kritische Toleranzen sicherzustellen.

Vertikale Bearbeitungszentren der VMC-Serie

CNC-programmierte Prozesse garantieren eine hochpräzise Teilefertigung und gewährleisten eine hervorragende Montagegenauigkeit und Gesamtproduktqualität.

60 m vollautomatische Strahlanlage

Jeder Kranträger wird nach dem Schweißen kugelgestrahlt. Dieser Prozess entfernt Oxidation, verbessert die Lackhaftung und beseitigt Restspannungen, um die Lebensdauer der Struktur zu verlängern.

ZS-Spritzlackierkabine

Alle Komponenten unserer elektrischen Seilzüge sind mit Hochleistungs-Polyurethanfarbe beschichtet, was eine langlebige und attraktive Oberfläche gewährleistet.

Prüfstände für Hebezeuge und Laufkatzen

100% elektrische Hebezeuge und Laufkatzen werden einzeln mit Strom versorgt und getestet, um die vollständige Funktionalität und Konformität sicherzustellen, bevor sie das Werk verlassen.

Vollständige Systemtestplattform

Jeder nicht standardmäßige oder neu entwickelte Kran wird vor der Auslieferung umfassenden Leistungstests auf unserem speziellen Vollsystemprüfstand unterzogen.

Kontaktieren Sie uns für ein Angebot

Verbessern Sie Ihre Hebevorgänge mit den in Deutschland entwickelten Lösungen von KRC. Kontaktieren Sie uns noch heute!