Who We Are

•KRC is the very first company who dedicated to the research, development and manufacture of European style cranes and intelligent cranes in China.

•KRC is one of the first batches of companies who indulge in the research, development and manufacture of industrial-grade multi-scene application winches.

•Up to now, KRC has owned 28 patented technologies in cranes, so as to push us to be one of the compilation units of Crane Design Manual and membership of Chinese Crane Standard Formulation.

•Chinese supreme A-class manufacturing and installation and maintenance qualifications is provided by KRC.

•KRC factory has made maximum double girder crane, which equipped with a lifting capacity of 360 tons and a span of 34.5 meters.

•KRC offered thousands of enterprises with multiple models, tonnages and spans of cranes, coming with full-matched design, installation works and other professional services.

•KRC is authorized to be the REGIONAL GENERAL AGENT by CMCO(US famous machinery manufacturing company) and DOLECO(the Germany Giant). Aiming to broaden market and offer professional installation and maintenance service.

•KRC serves industries including but not limited to iron and steel smelting, non-ferrous metal processing, automobile manufacturing, aircraft manufacturing, chemical industry, paper industry, manufacturing industry, construction industry, nuclear industry and military industry.

•KRC has been awarded the title of “Small Giant” enterprise of Henan Province. KRC’s technology research and development center is named provincial technology research and development center.

Why choose us

- 1.KRC will provide professional non-standard design services and complete production and delivery to meet different needs of customers and site conditions.

- 2.In order to cater to the needs of high-end customers, KRC will strictly and perfectly produce in accordance with the given drawings or suggestions. Aiming to bring the most attentive service to every single guest.

- 3.KRC will lay on the entire set of equipment and accessories requested by customers and offer one-stop solution for lifting and inventory handling problems.

- 4.Equipments of first tier brands are available for direct supply and customization from their Asia-Pacific factories.

- 5.KRC will prudently grasp each production link to ensure quality, delivery and meet the deadline.

- 6.KRC will provide professional technical training, installation support and after-sales service.

- 7.Cooperate with passing various tests to ensure the products meet different local standards.

- 8.OEM/ODM services.

Manufacturing Excellence at KRC

Professional R&D team

All engineers are professionally trained by ABUS (Germany) and utilize advanced 3D CAD and finite element analysis (FEA) tools to simulate stress distribution and motion for every crane system.

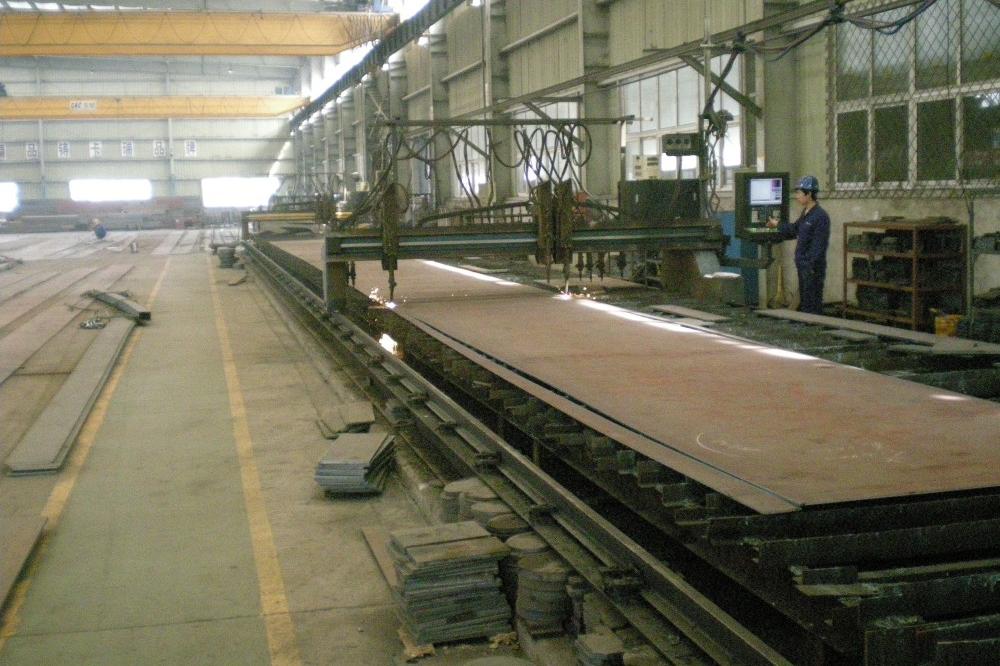

CNC Plasma Cutting System

Automated cutting of all custom-shaped components guarantees high dimensional accuracy and consistency across all lifting equipment.

40m CNC Flame Cutting Machine

All web plates are precisely cut in a single pass using CNC technology, ensuring accurate camber curves. No manual gas cutting is allowed—only CNC or specialized tooling is used for irregular shapes.

2500mm 400T WEH CNC Bending Machine

Used for detailed forming of small crane components, ensuring precise shaping and a premium final appearance.

CNC Horizontal Boring & Milling Machine

With 8-meter travel and full microcomputer control, end beam machining is completed in one setup to ensure strict straightness of wheel alignment and other critical tolerances.

VMC Series Vertical Machining Centers

CNC-programmed processes guarantee high-precision parts manufacturing, ensuring excellent assembly accuracy and overall product quality.

60m Fully Automatic Shot Blasting Line

Every crane girder undergoes shot blasting after welding. This process removes oxidation, enhances paint adhesion, and eliminates residual stress to extend structural lifespan.

ZS Spray Paint Booth

All components of our electric wire rope hoists are coated using high-performance polyurethane paint, ensuring a durable and attractive finish.

Hoist & Trolley Test Benches

100% of electric hoists and trolleys are individually powered and tested to ensure complete functionality and compliance before leaving the factory.

Full-System Test Platform

Every non-standard or newly developed crane undergoes comprehensive performance testing on our dedicated full-system test rig prior to delivery.

ISO 9001/ISO 14001/ISO 45001

Certification