Feature

- IP66 Grade Protection for enhanced durability.

- Helical Gear Multi-Drive Transmission for efficient lifting.

- Imported Wet Clutch Friction Pad with Overload Protection and Anti-Collision features, ensuring maintenance-free operation.

- Electromagnetic Brake for precise control.

- High-Performance Electric Motor for reliable and powerful lifting.

- G100 Grade Load Chains for robust load-bearing capacity.

- Compliance to German Standard BGV-D8 Regulation, CE Certified. (Optional Encoder for Digital Control.)

Product Description

The SU Stage Electric Hoist is designed for unparalleled performance in stage lifting applications. With IP66-grade protection, it stands resilient against environmental factors, ensuring durability and longevity. The helical gear multi-drive transmission provides efficient and smooth lifting operations, complemented by an imported wet clutch friction pad that offers overload protection and anti-collision features, all while maintaining a maintenance-free design.

Equipped with an electromagnetic brake and a high-performance electric motor, this hoist delivers precise control and powerful lifting capabilities. The G100 grade load chains ensure robust load-bearing capacity, making it suitable for a variety of stage setups.

Compliant with German standard BGV-D8 regulation and CE certified, the SU Stage Electric Hoist prioritizes safety and quality. For those seeking advanced control, an optional encoder is available to realize digital control, providing even greater flexibility in stage operations.

Please contact us for more detailed parameters

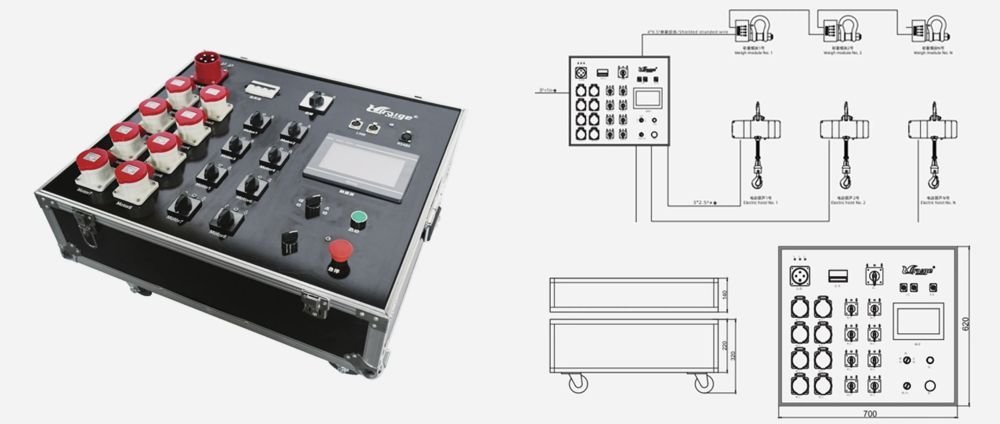

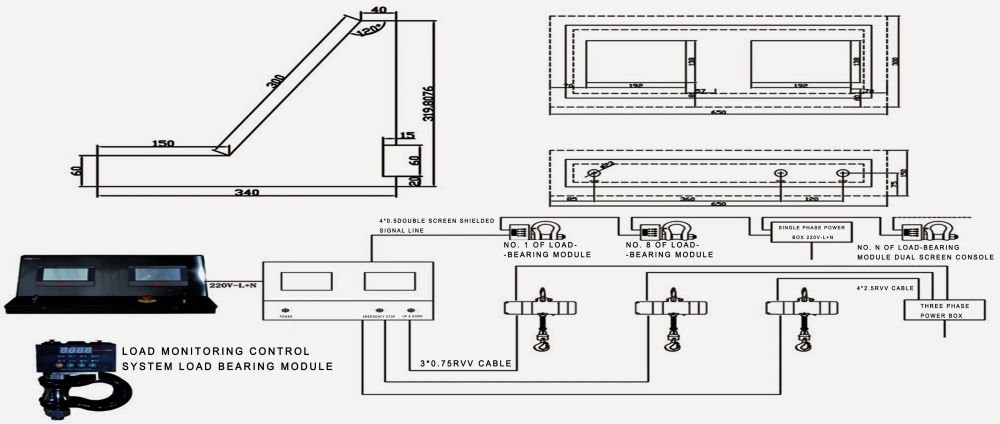

- The wired load monitoring and control system is designed for comprehensive functionality, supporting multi-line connections with options for 4, 8, 12, 24 channels, extendable up to 250 channels. Achieve group control operation to enhance work efficiency.

- The aviation box’s corrosion-resistant outer shell caters to the needs of the mobile performance market, ensuring easy portability and transportation.

- Multiple control gears offer convenience and emergency stop buttons for swift handling in critical situations.

- High-quality aviation plugs with grounding pins and insulation materials prevent current leakage and short circuits, ensuring stable signal transmission.

- Main components, all imported brands, have undergone rigorous aging tests for reliability.

- Equipped with a weighing module and controller, the load capacity data is intuitively displayed on an electronic screen, ensuring operational safety.

- Power supply is 380V 3ph+N+PE, ensuring safe operation.

- The touch screen controller, a digital control system, centralizes all options on the LCD touch screen for a digital display.

- Independently control the lifting and lowering of one or more electric hoists, with the ability to group points, saving time in layout drawings.

- Ergonomically designed LCD control panel for a sleek appearance and user-friendly operation.

- Separate console and integrated circuit cabinet design with a single signal line, enhancing convenience and flexibility.

- Handheld operation console with a joystick-type lever for controlled and safe operation.

- Emergency stop button on the control panel ensures a swift response in emergencies.

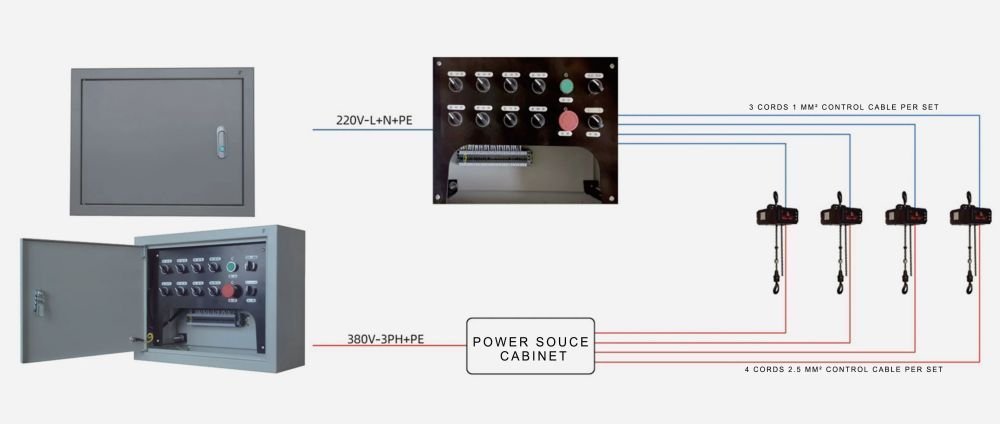

- The HGK-D series synchronous controller is designed for fixed installations with a control voltage of 36V.

- All electrical appliances undergo aging testing, and main components are imported brands.

- Wall-mounted cabinet, customizable for electric hoist points.

- Jog and jog knobs for enhanced operational convenience.

- Power supply is 220V with grounding for construction safety.

- Optional wireless remote control for added flexibility.

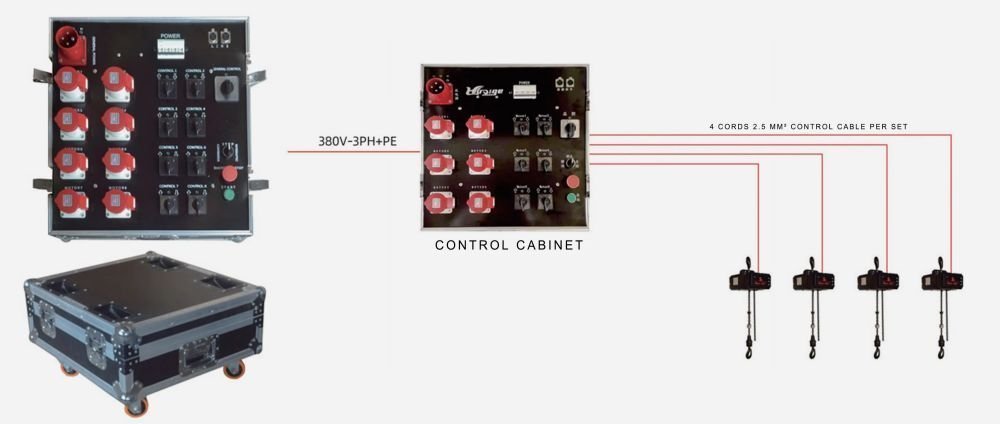

- The advanced synchronous controller boasts an impressive capacity, capable of handling up to 46 channels simultaneously, providing extensive control options for your electric hoists.

- Rigorous quality assurance: Every electrical component of the synchronous controller undergoes thorough aging testing, guaranteeing reliability and longevity. The main components are sourced from reputable imported brands, ensuring top-tier performance.

- Precision Control at Your Fingertips: The controller features a heavy-duty rotary directional switch, offering a separate power supply for each electric hoist. This design significantly enhances controllability, providing precise and individualized command over each hoist. The fast serial interface enables seamless linkage between multiple controllers for synchronized operations.

- Mobile-Ready Design: The outer shell is thoughtfully crafted in the design of an aviation box, meeting the specific needs of the mobile performance market. This design ensures that the controller is easy to carry and transport, facilitating flexibility in various performance setups.

- Robust Power Supply: The controller operates on a reliable 380V power supply, grounded for optimal construction safety. This robust power provision ensures consistent and safe performance in diverse operational environments.

- Optional Wireless Remote Control: For added convenience and flexibility, the controller offers an optional wireless remote control feature. This optional addition provides operators the freedom to control and manage the hoists remotely, further enhancing operational efficiency.

- The synchronous controller handles up to 46 channels, providing separate power supply for each electric hoist.

- All electrical appliances undergo aging testing, and main components are imported brands.

- Heavy-duty rotary directional switch with a fast serial interface for linkage between multiple controllers.

- Aviation box outer shell for easy transportation in the mobile performance market.

- Power supply is 380V with grounding for construction safety.

- Optional wireless remote control for added convenience.

For More Intelligent Customization

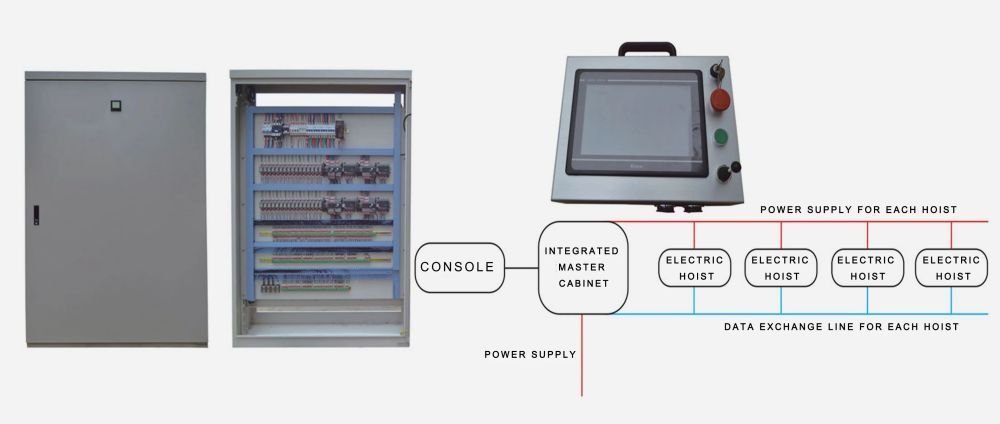

PLC Control System for Precise Stage Operations

Integrated Control Cabinet:

- All-in-one cabinet for both power supply cables and signal lines, simplifying maintenance and commissioning processes.

Versatile Applications:

- Ideal for diverse settings such as banquets, bars, and theatre performances, offering adaptable solutions for various stage scenarios.

Advanced Frequency Converter:

- Built-in high-performance vector frequency converter ensures steady and smooth speed adjustment for both lifting and descending actions.

Intuitive Touch Screen Console:

- Touch screen console facilitates grouping control for each hoist’s lifting/descending, real-time lifting height display, static point positioning, and more.

Precision Positioning:

- Achieves repeated positioning accuracy of ±5mm, ensuring exact and reliable stage movements.

Safety and Operation:

- Touch screen console connects to the PLC master electronic control cabinet, featuring emergency stop and a rocker handle for user-friendly operation.

Scenario Programming:

- PLC system stores scenarized application programs, enabling the execution of continuous actions for multiple styles. Perfectly realizes required stage action effects.

Independent Design for Safety:

- Console and master cabinet designed and produced independently, providing enhanced safety and better visualization for real-time monitoring of hoist actions.

Power Supply:

- Operates on a reliable 380V power supply (L1+L2+L3+N+E) to ensure stable and consistent power delivery.

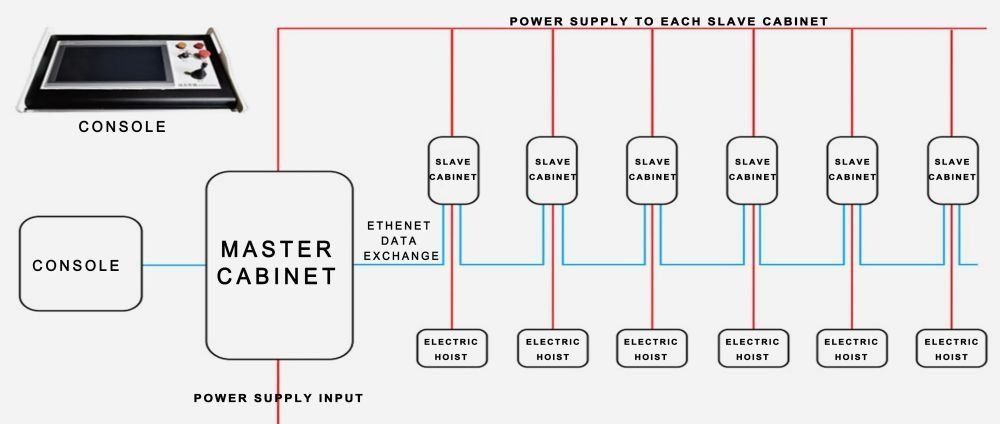

Ethernet Programmable Control System for Effortless Stage Management

Integrated Drive and Control Design:

Streamlined design integrates drive and control systems. A single signal line and power line are all you need to control the entire system.

Distributed Electric Cabinets for Touring Performances:

2. Designed with distributed electric cabinets for each electric hoist, minimizing wiring and signal interference. Quick installation and suitable for touring performances.

Advanced Vector Frequency Converter:

3. Built-in high-performance vector frequency converter ensures smooth speed adjustment for steady lifting and descending. Customizable motion speeds add versatility.

Truss-Mounted Slave Control Cabinets:

4. Slave control cabinets mount on trusses with ISO standard connection ports, reducing wiring complexity. Plug and play without additional conversion.

Configurable Console with Touch Screen:

5. Console features a configuration panel and touch screen display. Execute ramp start/stop, static point positioning, real-time display of lifting height, and more.

Precision Positioning:

6. Achieves exceptional repeated positioning accuracy of ±1mm, ensuring precise and reliable stage movements.

Smart Load Monitoring and Safety Features:

7. PLC master electronic control cabinet measures electric hoists’ loading weight, monitors each hoist’s loading situation, and automatically cuts off power supply if overloaded by 120%, sending alerts for corrective action (optional).

Heavy Loading Connectors for Signals:

8. Heavy loading connectors transfer hoists’ position limit signals and encoder signals, ensuring accurate and secure communication.

Long-Distance Console Operation:

9. Supports console operation up to 100 meters away from hoists, providing flexibility in stage management.

Ethernet Master Electronic Control Cabinet:

Five-cord plug-in connector for power source connection. Rated power supply voltage: 380V (L1+L2+L3+N+PE).

CE 380V socket output with each line rated at 32A. Working seamlessly with the master control cabinet, it can achieve various stage scenes, vertical lifting/descending, and angle changes.

32A master power source output, supporting 4-6 slave electronic control cabinets with minimal wiring.

Load Monitoring System for Enhanced Safety and Control

Dual-Screen Control:

- Screen 1 displays load monitoring, providing a visual representation of the weight of each lifting point. This safety observation screen allows customers to better understand the dynamics of the lifting points. The built-in operation panel enhances user engagement.

Electric Hoist Control Display:

- Screen 2 is dedicated to electric hoist control, featuring an LCD touch screen with digitized display of all control options. The controller allows individual control of one or more electric hoists. Grouping each point with a purpose name and note streamlines operations without the need for layout drawings.

Ergonomic LCD Console:

- The LCD console is ergonomically designed for a comfortable user experience. It combines an exquisite appearance with simple and intuitive operation.

Separate Console and Circuit Cabinet:

- The operation console and integrated circuit cabinet are designed separately. A single signal line is all that is needed to connect them, increasing convenience and operational flexibility.

Joystick-Type Operating Lever:

- The handheld console features a joystick-type operating lever. The electric hoist is powered only when the lever is pushed up or pulled down. Resetting the lever to the middle stops sending action signals, enhancing control and security during non-operation.

Emergency Stop Button:

- The operating console is equipped with an emergency stop button, allowing quick cutoff of the control system and power supply in emergencies, preventing safety accidents.

Power Supply Details:

- The cabinet operates on a 220V single three-cords system, ensuring a reliable and stable power supply.

Load Monitoring System for Enhanced Safety and Control

Dual-Screen Control:

- Screen 1 displays load monitoring, providing a visual representation of the weight of each lifting point. This safety observation screen allows customers to better understand the dynamics of the lifting points. The built-in operation panel enhances user engagement.

Electric Hoist Control Display:

- Screen 2 is dedicated to electric hoist control, featuring an LCD touch screen with digitized display of all control options. The controller allows individual control of one or more electric hoists. Grouping each point with a purpose name and note streamlines operations without the need for layout drawings.

Ergonomic LCD Console:

- The LCD console is ergonomically designed for a comfortable user experience. It combines an exquisite appearance with simple and intuitive operation.

Separate Console and Circuit Cabinet:

- The operation console and integrated circuit cabinet are designed separately. A single signal line is all that is needed to connect them, increasing convenience and operational flexibility.

Joystick-Type Operating Lever:

- The handheld console features a joystick-type operating lever. The electric hoist is powered only when the lever is pushed up or pulled down. Resetting the lever to the middle stops sending action signals, enhancing control and security during non-operation.

Emergency Stop Button:

- The operating console is equipped with an emergency stop button, allowing quick cutoff of the control system and power supply in emergencies, preventing safety accidents.

Power Supply Details:

- The cabinet operates on a 220V single three-cords system, ensuring a reliable and stable power supply.