Colaboração Sino-Alemã

Sistemas de guindastes inteligentes KRC

Automação de última geração para elevação industrial

Visão geral do produto

Os sistemas de guindastes inteligentes da KRC são projetados para automatizar os processos de movimentação de materiais com segurança, precisão e eficiência avançadas. Integrando posicionamento inteligente, medição a laser, detecção por radar e lógica baseada em IA, nossos guindastes otimizam a logística, minimizam a intervenção manual e garantem operações seguras e confiáveis em ambientes complexos.

- Inovação Sino-Alemã: Parceria com a ABUS para tecnologia de ponta em guindastes.

- Liderança da Indústria: Primeiro na China em guindastes inteligentes e de estilo europeu.

- Excelência comprovada: “Pequeno Gigante” de Henan e centro provincial de P&D.

Principais características

- Automação Inteligente: Alcance do laser, posicionamento do codificador e reconhecimento de laser 3D para manuseio preciso de materiais.

- Controle Anti-Oscilação: Garante uma operação estável, aumentando a segurança e a eficiência.

- Sistema de Gestão Inteligente: O controle independente e o gerenciamento de armazém reduzem custos e melhoram a eficiência.

- Segurança em primeiro lugar: Estacionamento automático, cortinas de luz e radar garantem a segurança do pessoal em áreas não fechadas.

- Soluções Personalizadas: Lógica de controle personalizada e sistemas de gerenciamento de armazém, desenvolvidos com parceiros universitários, aproveitam pesquisas avançadas para otimizar o desempenho do guindaste de acordo com as necessidades específicas do cliente.

Aplicações

- Segurança de Pessoal: O estacionamento automático e o radar garantem uma passagem segura sem a necessidade de entrada do operador nas áreas de armazenamento.

- Eficiência de armazenamento: Ferramentas especializadas aumentam a capacidade de armazenamento em 30% usando princípios FIFO para gerenciamento de estoque simplificado.

- Soluções Personalizadas: A lógica de controle personalizada otimiza os movimentos do guindaste para layouts de armazém específicos, enquanto um sistema independente de gerenciamento de armazém, desenvolvido com parceiros universitários, automatiza o armazenamento/recuperação, reduzindo os custos de mão de obra.

- Segurança: O engate automático do gancho minimiza os riscos do manuseio de metal fundido.

- Controle de fluxo preciso: O controle de inclinação autoaprendizagem, personalizado por meio de colaboração universitária, ajusta os ângulos de vazamento para uma fundição estável.

- Soluções Personalizadas: A lógica de controle personalizada garante posicionamento preciso baseado em radar, enquanto sistemas de gerenciamento especializados oferecem suporte ao manuseio seguro e eficiente de materiais de alto risco.

- Eficiência de empilhamento: Empilhadeiras de corredor otimizam o espaço em armazéns não fechados, reduzindo o espaçamento entre prateleiras.

- Garantia de Segurança: Vários sensores garantem posicionamento preciso e protegem o pessoal.

- Soluções Personalizadas: A lógica de controle desenvolvida pela universidade e o gerenciamento de armazém integrado ao MES permitem armazenamento/recuperação automatizados, adaptados aos layouts e fluxos de trabalho específicos do cliente.

Soluções versáteis para ambientes industriais avançados:

- Indústria química: Manuseio seguro e automatizado de materiais perigosos.

- Metalurgia: Fundição precisa e elevação de componentes pesados.

- Armazenagem: Armazenamento e recuperação eficientes em armazéns estéreo e planos.

- Indústria Ferroviária: Confiável pela CRRC para manuseio de componentes de locomotivas.

Especificações técnicas

| Parâmetro | Especificação |

|---|---|

| Capacidade de elevação | Até 100 toneladas |

| Extensão | Até 36m |

| Velocidade de elevação | 0,4-16 m/minuto |

| Velocidade de deslocamento do carrinho | 2-20 m/minuto |

| Velocidade de deslocamento do guindaste | 5-60m/min |

| Sistema de controle | Navegação a laser, posicionamento automático, gerenciamento inteligente |

| Fonte de energia | 380 V/50 Hz (personalizável) |

Projetos de Sucesso

A KRC entregou mais de Mais de 100 sistemas de guindastes inteligentes para grandes clientes, incluindo:

Sail Group — Guindaste guiado a laser (2018)

MCC Sul — Guindaste inteligente magnético de sucata (2018)

Xinxing Ferro Dúctil — Guindastes de fundição e armazém (2018–2019)

Plantas petroquímicas — Guindastes inteligentes à prova de explosão (2020–2021)

Huamao Mining — Guindastes programáveis interligados (2020)

Observação: todos os parâmetros podem ser adaptados para atender ao seu local e às condições de trabalho específicos.

processo de produção

Equipe profissional de P&D

Todos os engenheiros são treinados profissionalmente pela ABUS (Alemanha) e utilizam ferramentas avançadas de CAD 3D e análise de elementos finitos (FEA) para simular a distribuição de tensão e movimento de cada sistema de guindaste.

Sistema de corte de plasma CNC

O corte automatizado de todos os componentes com formato personalizado garante alta precisão dimensional e consistência em todos os equipamentos de elevação.

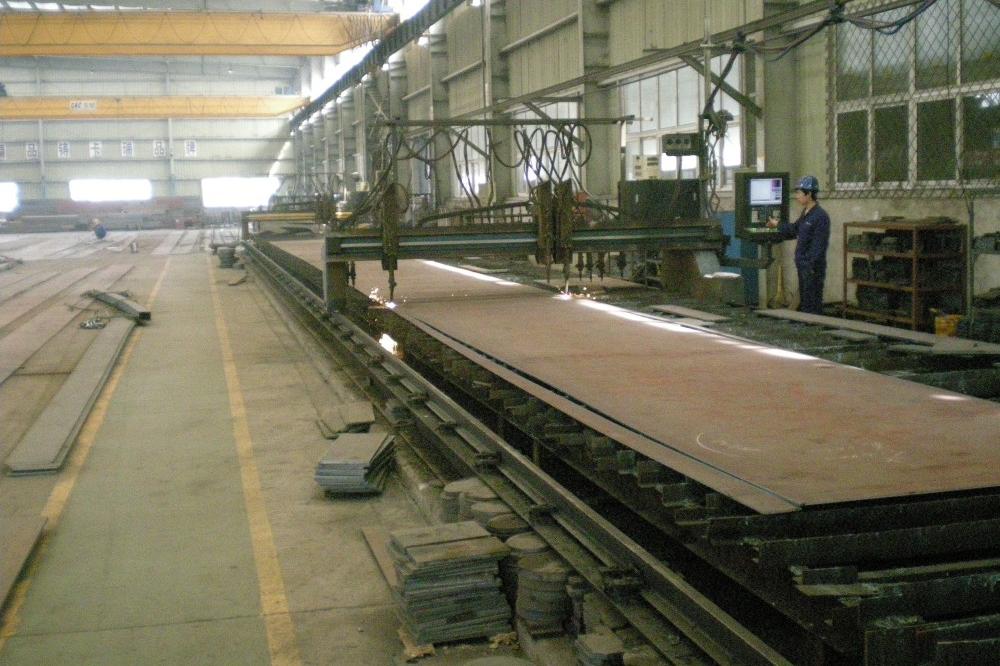

Máquina de corte a chama CNC de 40 m

Todas as chapas de alma são cortadas com precisão em uma única passagem usando tecnologia CNC, garantindo curvas de cambagem precisas. Não é permitido corte manual a gás — apenas CNC ou ferramentas especializadas são usadas para formas irregulares.

Máquina de dobra CNC WEH de 2500 mm e 400 T

Usado para conformação detalhada de pequenos componentes de guindaste, garantindo modelagem precisa e uma aparência final premium.

Máquina de furação e fresagem horizontal CNC

Com curso de 8 metros e controle total do microcomputador, a usinagem da viga final é concluída em uma única configuração para garantir a retidão rigorosa do alinhamento das rodas e outras tolerâncias críticas.

Centros de usinagem verticais da série VMC

Os processos programados por CNC garantem a fabricação de peças de alta precisão, assegurando excelente precisão de montagem e qualidade geral do produto.

Linha de jateamento totalmente automática de 60 m

Todas as vigas de guindaste passam por jateamento após a soldagem. Esse processo remove a oxidação, melhora a aderência da tinta e elimina tensões residuais, prolongando a vida útil da estrutura.

Cabine de pintura spray ZS

Todos os componentes dos nossos talhos elétricos de cabo são revestidos com tinta de poliuretano de alto desempenho, garantindo um acabamento durável e atraente.

Bancadas de teste para guinchos e carrinhos

Os guindastes e carrinhos elétricos 100% são energizados e testados individualmente para garantir total funcionalidade e conformidade antes de saírem da fábrica.

Plataforma de teste de sistema completo

Cada guindaste não padronizado ou recém-desenvolvido passa por testes de desempenho abrangentes em nosso banco de testes dedicado de sistema completo antes da entrega.

Entre em contato conosco para um orçamento

Aprimore suas operações de elevação com as soluções de engenharia alemã da KRC. Entre em contato conosco hoje mesmo!