Introduction

When you think about the heavy lifting and pulling tasks in industries like mining, construction, and marine, one tool that stands out is the industrial winch. But what exactly is an industrial winch, and why is it so crucial in these industries?

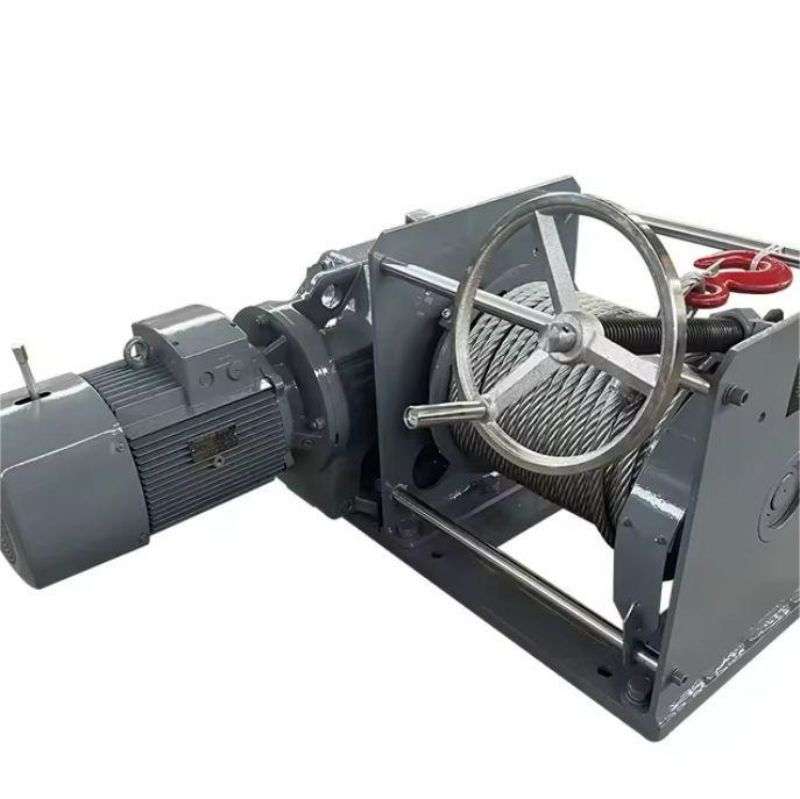

An industrial winch is a mechanical device used to pull in (wind up) or let out (wind out) or otherwise adjust the tension of a rope or wire rope (also called “cable” or “wire cable”). The device consists of a spool and an attached hand crank. When it comes to heavy-duty applications, these winches are motorized and come with various safety features.

Types of Industrial Winches

Manual Winches

Manual winches are operated by hand and are suitable for lighter tasks where precision is key. They are commonly used in small construction sites and for personal use.

Electric Winches

Electric winches are powered by electricity and are perfect for medium to heavy-duty tasks. They are popular in construction and manufacturing industries due to their efficiency and ease of use.

Pneumatic Winches

Pneumatic winches operate using compressed air. They are ideal for environments where electricity could pose a risk, such as in explosive atmospheres.

Key Components of Industrial Winches

- Motor:The motor powers the winch and can be electric, hydraulic, or pneumatic. Its power rating determines the winch’s capacity and speed.

- Drum:The drum is the cylinder onto which the rope or cable is wound. Its size and design affect the winch’s performance.

- Brake System:The brake system ensures the load remains stationary when the winch is not in operation. Automatic braking systems enhance safety by preventing accidental load release.

- Control System:The control system allows the operator to control the winch’s speed and direction. Advanced winches come with remote control features for added convenience.

Key Components of Industrial Winches

Mining

In mining, winches are used to hoist materials and workers, making operations safer and more efficient.

Construction

Winches are essential in construction for lifting heavy materials and equipment to various heights.

Marine

In the marine industry, winches are used for anchoring, towing, and mooring operations, ensuring smooth and safe sailing.

Advantages of Using Industrial Winches

Efficiency and Speed

Winches significantly reduce the time and effort required to move heavy loads, enhancing operational efficiency.

Safety Features

Modern winches come with various safety features, such as automatic brakes and overload protection, minimizing the risk of accidents.

Versatility

Winches are versatile tools that can be used in numerous industries and applications, from lifting to pulling and tensioning.

Factors to Consider When Choosing an Industrial Winch

Load Capacity

Choose a winch with a load capacity that meets or exceeds your operational requirements.

Power Source

Consider the availability of power sources in your work environment when selecting between electric, hydraulic, or pneumatic winches.

Environment

The environment where the winch will be used can impact its performance. For instance, marine environments require corrosion-resistant winches.

Cost

Evaluate the total cost of ownership, including purchase price, installation, maintenance, and potential downtime costs.

Installation and Maintenance

Proper installation is crucial for the winch’s performance and safety. Follow the manufacturer’s guidelines and consider hiring a professional for installation.

Regular maintenance, including lubrication, inspection, and parts replacement, ensures the winch operates smoothly and safely.

Safety Tips for Operating Industrial Winches

Ensure that operators are adequately trained in using the winch and are aware of all safety protocols.

Conduct regular inspections to identify and address potential issues before they lead to accidents.

Have clear emergency procedures in place and ensure all operators are familiar with them.

Top Brands in the Market

Ingersoll Rand

Ingersoll Rand is famous for its excellent engineering design and manufacturing standards. Its winches usually use sturdy materials and advanced technology to ensure reliable operation in various harsh working conditions.

Thern

Thern manufactures a variety of industrial winches suitable for heavy lifting and pulling applications. Their products are known for versatility and customization, widely used in construction, mining, and marine industries.

Columbus McKinnon (CMCO)

Columbus McKinnon owns brands like CM, Coffing, and Yale, offering a wide range of industrial winches praised for their superior design and robust construction.

Future Trends in Industrial Winches

Automation

Automation will continue to enhance the efficiency and safety of winch operations, reducing the need for manual intervention.

Enhanced Safety Features

Future winches will come with even more advanced safety features, such as AI-based monitoring systems.

Sustainability

Sustainable winches made from eco-friendly materials and designed for energy efficiency will become more prevalent.

Conclusion

Industrial winches are indispensable tools in various industries, offering efficiency, safety, and versatility. By understanding the different types, components, and applications of winches, you can make informed decisions about their use and maintenance. As technology advances, we can expect even more innovative and sustainable winch solutions in the future.

FAQs

What is the lifespan of an industrial winch?

The lifespan of an industrial winch depends on its usage, maintenance, and the environment in which it operates. Regular maintenance can extend its life significantly.

How often should winches be inspected?

Winches should be inspected regularly, with frequency depending on usage intensity. A general recommendation is to conduct a thorough inspection at least once a month.

Can winches be customized?

Yes, many manufacturers offer customization options to meet specific operational needs, including load capacity, power source, and additional features.