Key Features for Wind Turbine Electric Winch

In the ever-evolving wind energy sector, the demand for specialized equipment that ensures both safety and efficiency is paramount. This is particularly true for wind turbine installations, where the challenges of high-altitude operations necessitate robust and reliable tools. Recently, we had the opportunity to deliver a custom-made electric winch designed specifically for a key wind power project in Australia, showcasing our commitment to providing practical and cost-effective solutions for the wind energy industry.

Meeting the Unique Demands of Wind Turbine Installation

The project in Australia presented several unique challenges. The remote location and the sheer height of the wind turbines required a solution that could perform under extreme conditions while ensuring the safety of the operators. Understanding these requirements, we designed a customized electric winch that not only met the project’s specifications but also exceeded the customer’s expectations.

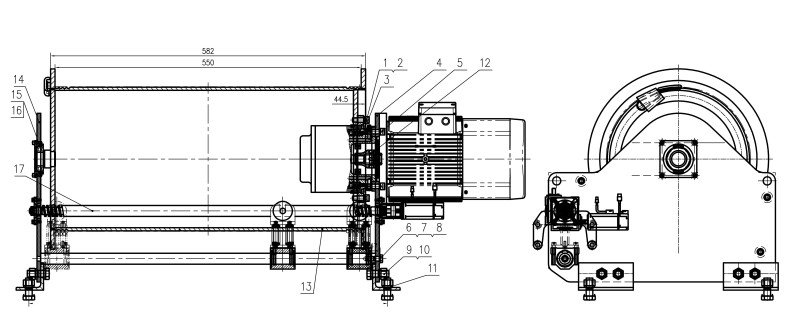

The electric winch was engineered with a ZD-4.5KW motor and P250T3197-2W reducer, offering the durability needed to withstand harsh environmental conditions. This was a crucial aspect, given the frequent and prolonged use that is typical in wind turbine installations. Additionally, the winch was equipped with a 13mm wire rope with a capacity of 360 meters, specifically chosen for its ability to handle the long-distance lifting necessary for the installation of tall wind turbine structures.

Ensuring Safety and Productivity

Safety is at the forefront of our design philosophy, and this customized winch was no exception. The inclusion of an electromagnetic spring-applied failsafe brake provides peace of mind by ensuring that the load remains securely held during operations, even in the event of power failure. Furthermore, the winch was fitted with emergency stop functions and up-and-down limit switches, which offer additional layers of protection and control, ensuring that the installation process could proceed without unnecessary risks.

The high lifting speed of 12m/min was another critical feature, allowing the project team to complete tasks more quickly, thereby reducing downtime and maximizing productivity. This efficiency is essential in wind turbine projects, where time is often of the essence, and delays can lead to significant cost overruns.

A Practical and Cost-Effective Solution

Our approach to this project in Australia underscores our commitment to delivering tailored solutions that align with the specific needs of our customers. The customized electric winch provided a practical and cost-effective answer to the challenges posed by high-altitude wind turbine installations. By focusing on safety, durability, and efficiency, we were able to support the successful completion of this wind power project.

Conclusion

This case study highlights the importance of specialized equipment in the wind energy sector and our ability to deliver customized solutions that meet the demanding requirements of this industry. For professionals engaged in wind turbine installations, the Wind Turbine Installation and Maintenance Electric Winch offers an essential tool that combines performance, safety, and reliability.

To learn more about the high-performance winch used in this project and how it can benefit your wind energy operations, visit the product page.