Feature

Durability

Rugged all-steel construction with long-life design

Corrosion-resistant marine-grade paint and bolting

Heavy-duty corrosion-resistant load chain

Available with Gear or Piston air motors known for progressive speed control and low maintenance

Safety

Automatic fail-safe multi-disc motor brake on hoist

Ergonomic pendant with optional emergency stop/start feature

Upper and lower limit switches for over-travel protection

Performance

Low (LBS Series) and Ultra-Low (ULBS Series) headroom profiles for easy BOP stack handling in space-restricted areas

Bottom block mounted on bearing with external lubrication point and water drain

Multiple attachment options: clevis, shackle, or bottom hook

Reliable, virtually maintenance-free air motor for continuous heavy-duty use

Product Description

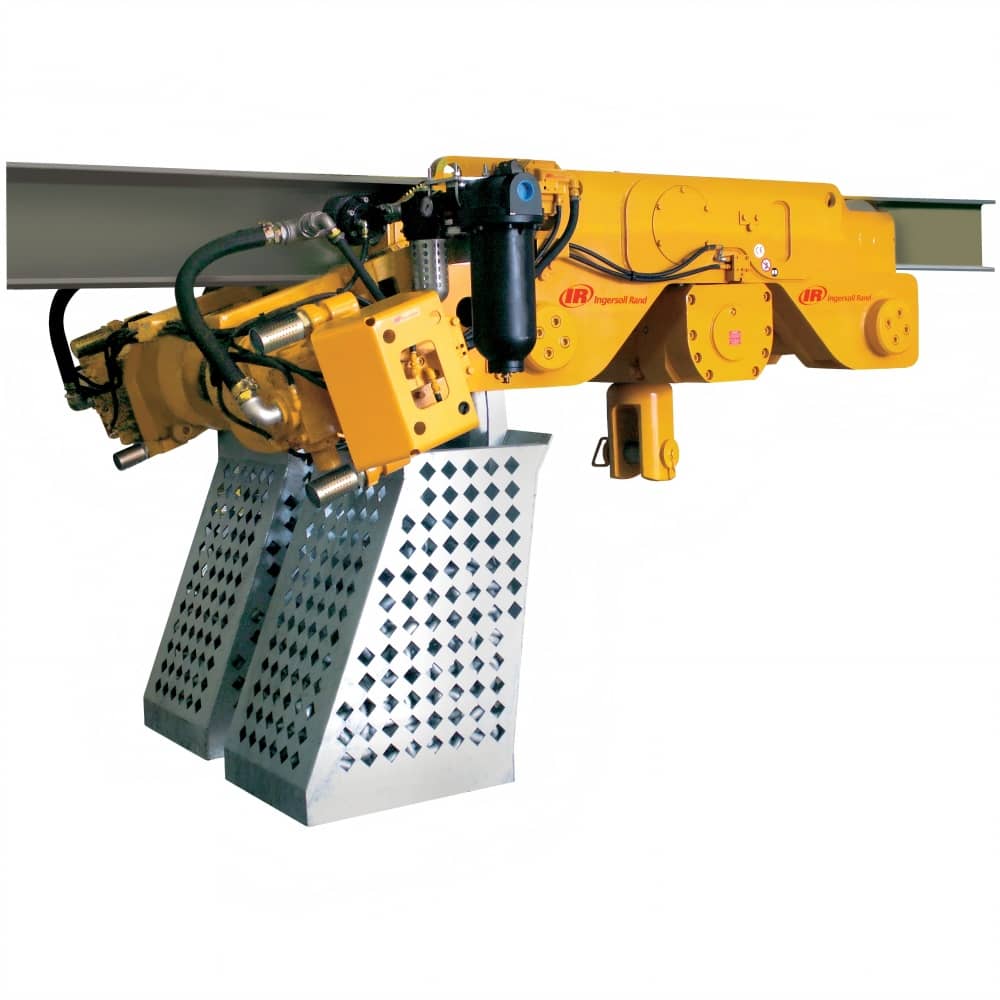

The Ingersoll Rand Liftchain Low & Ultra-Low Headroom Air Hoist BOP Handling Systems are engineered specifically for applications where space is limited but safety and performance cannot be compromised.

Built to withstand harsh offshore and onshore drilling environments, these systems combine all-steel construction with marine-grade corrosion protection for extended service life. The LBS Series offers a low-profile solution, while the ULBS Series provides an ultra-compact design for maximum clearance during BOP stack operations.

Both models are equipped with advanced safety features, including fail-safe braking systems and limit switches, while providing exceptional performance with gear or piston air motor options.

Applications

Offshore oil rigs with restricted space

Onshore drilling rigs requiring compact lifting systems

Harsh marine and corrosive environments

Precision handling of Blowout Preventer (BOP) stacks

With global recognition and compliance with NPD, DNV, and ABS industry standards, Ingersoll Rand’s Low and Ultra-Low Headroom Air BOP Handling Systems are trusted worldwide for safe and efficient oilfield lifting operations.