In the world of live performances, stage design is crucial for creating an unforgettable experience for the audience. Stage lifting equipment, such as stage hoists, stage electric hoists, and stage chain hoists, has become indispensable in modern stage design, enabling innovative and dynamic performances.

Electric hoists, equipped with electronic controllers, play a significant role in this transformation. There are two main types of electric hoists used in stage design:

Downside Hung Electric Hoists

- Usage: Ideal for touring performances and concerts.

- Advantages: Compact size and easy to transport, making them perfect for temporary setups and frequent relocations.

Upside Hung Electric Hoists

- Usage: Commonly used in permanent installations such as large meeting halls, theaters, and banquet halls.

- Advantages: Provides greater stability and a higher safety factor, suitable for more demanding and long-term environments.

Moreover, electric hoists can be customized with specific specifications and integrated with computer control systems to adapt to various environments and scenes, ensuring optimal performance and safety in any setting.

Enhancing Stage Design and Production with Lifting Equipment

Stage lifting equipment significantly enhances stage design and production by allowing for smooth, dynamic movements and special effects. For instance, stage electric hoists can be used to elevate platforms, create flying effects, or quickly change sets, adding a new dimension to performances. The versatility of stage hoists enables designers to experiment with various elements, resulting in more engaging and visually stunning productions.

Examples of Innovative Stage Designs Using Lifting Equipment

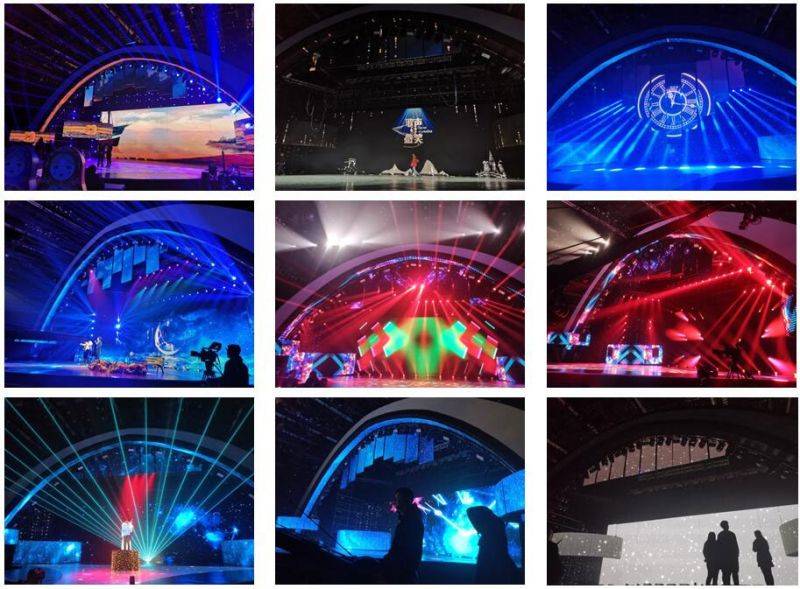

Spring Festival Gala

In theater productions, stage chain hoists are used to manage scene changes efficiently. By lifting and lowering heavy sets seamlessly, these hoists ensure that the transitions between scenes are smooth, maintaining the flow of the performance.

Large-scale concerts often utilize stage electric hoists to lift platforms and performers, creating dramatic entrances and exits. This not only enhances the visual appeal but also adds a level of excitement and surprise for the audience.

Heilongjiang TV Singing and Smiling

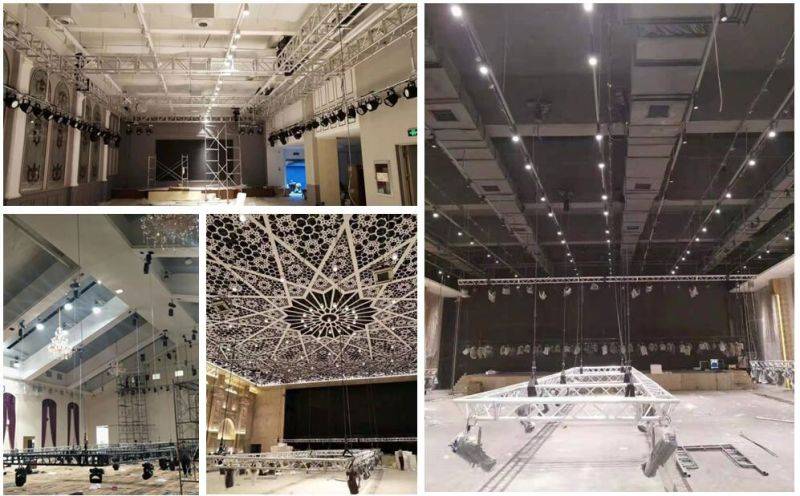

Construction of Beijing Shangri La Hotel

Award shows and large events frequently use stage lifting equipment to handle heavy lighting rigs and props. This allows for quick adjustments and reconfigurations, ensuring that the stage setup meets the specific requirements of different segments of the show.

Future Trends in Stage Lifting Technology

The future of stage lifting technology looks promising, with advancements focusing on digital control systems and automation. Integrating digital controllers and PLC systems with stage hoists allows for precise movements and synchronization, enhancing the overall performance. Additionally, the development of more compact and lightweight lifting equipment will provide greater flexibility in stage design, enabling more creative and complex setups.