Introduction aux normes relatives aux grues antidéflagrantes

Nous savons que le choix de la certification antidéflagrante appropriée pour les ponts roulants et les palans est essentiel à la sécurité d'exploitation en environnements dangereux. En tant que leader du secteur, nous sommes convaincus que le choix de la certification antidéflagrante appropriée pour les ponts roulants et les palans est crucial pour la sécurité opérationnelle. fabricant de grues industrielles Forts de plusieurs décennies d'expérience sur les marchés internationaux, nous savons que le respect des normes antidéflagrantes n'est pas qu'une simple obligation réglementaire : il est essentiel à la protection du personnel, des biens et de la productivité. Ce guide complet examine les trois principaux systèmes de certification antidéflagrante : les normes ATEX (européenne), IECEx (internationale) et GB (chinoise), et propose des comparaisons techniques détaillées pour vous aider dans le choix de vos équipements.

Comprendre les principes fondamentaux de la certification antidéflagrante

La certification antidéflagrante représente une approche systématique de la conception des équipements visant à prévenir l'inflammation dans les atmosphères dangereuses contenant des gaz inflammables, des vapeurs ou des poussières combustibles. Ces normes imposent des contrôles d'ingénierie spécifiques, des choix de matériaux et des protocoles d'essai afin de garantir que les composants électriques et mécaniques ne puissent pas générer d'étincelles, d'arcs électriques ou de températures excessives susceptibles de provoquer des explosions. ponts roulants et pour les appareils de levage utilisés dans des secteurs comme le traitement chimique, le pétrole et le gaz, l'exploitation minière et la fabrication pharmaceutique, le respect de ces normes est non négociable pour la sécurité opérationnelle.

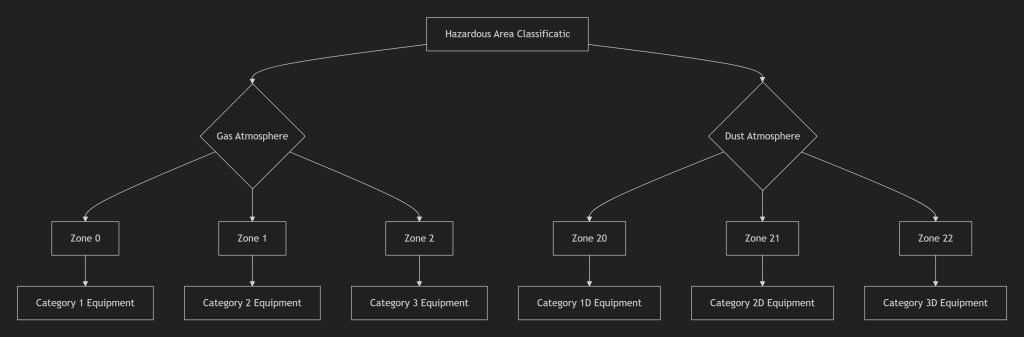

Systèmes de classification des zones dangereuses

Zone 0 : Atmosphère explosive présente en permanence ou pendant de longues périodes Zone 1 : Atmosphère explosive probable en conditions normales d'exploitation Zone 2 : Atmosphère explosive peu probable dans des conditions normales

Zone 20 : Présence continue de poussières combustibles Zone 21 : Poussières combustibles probables en fonctionnement normal Zone 22 : Poussières combustibles peu probables dans des conditions normales

Normes ATEX : Directive européenne 2014/34/UE

Cadre réglementaire et portée

Catégories d'équipements et niveaux de protection

Méthodes de protection : Ex ia (sécurité intrinsèque), Ex ma (encapsulation) Facteurs de sécurité requis : double redondance ou mesures de sécurité renforcées

Méthodes de protection : Ex d (antidéflagrant), Ex e (sécurité accrue), Ex ib (sécurité intrinsèque) Documentation complète incluant un dossier technique de construction

Méthodes de protection : Ex n (anti-étincelles), Ex ec (sécurité accrue) procédure simplifiée d'évaluation de la conformité

Processus de certification ATEX

Tests d'élévation de température pour vérifier que les températures de surface restent inférieures aux points d'inflammation Tests d'impact pour garantir l'intégrité de l'enceinte sous contrainte mécanique Tests de protection contre les infiltrations (IP54 minimum pour les équipements électriques) Essais d'allumage par étincelle pour les matériaux non métalliques

Certification IECEx : Normalisation internationale

Reconnaissance et acceptation mondiales

Exigences techniques clés

Groupe I : Applications minières (environnements méthane) Groupe II : Industries de surface (diverses classifications de gaz)

T1 : 450 °C maximum T6 : 85 °C maximum (très strict)

IIC : Hydrogène, acétylène (le plus volatil) IIB : Éthylène IIA : Propane

Avantages de la certification IECEx

Le système IECEx offre des avantages considérables pour les opérations internationales : Une seule certification acceptée dans plusieurs pays Exigences de documentation simplifiées grâce au système d'évaluation de la qualité IECEx Réduction des redondances en matière de tests grâce à des accords de reconnaissance mutuelle Certification intégrée des compétences du personnel (Certification IECEx des compétences du personnel)

Normes GB : le cadre réglementaire de la Chine

Aperçu des normes nationales chinoises

Système de classification standard GB

Ga/Da : Protection très élevée (équivalente à la zone 0/20) Gb/Db : Protection élevée (équivalent à la zone 1/21) Gc/Dc : Protection renforcée (équivalent à la zone 2/22)

Symbole Ex Type de protection (d, e, i, etc.) Catégorie d'équipement (I, II, III) classe de température niveau de protection des équipements

Processus de certification GB

essais de type effectués par des laboratoires chinois désignés Audits d'usines réalisés par des inspecteurs agréés par la SAMR Tests d'échantillonnage pour chaque catégorie de produits Audits de suivi annuels pour maintenir la certification

Analyse comparative : normes ATEX, IECEx et GB

Applicabilité géographique et accès au marché

| Aspect | ATEX (UE) | IECEx (Global) | Normes GB chinoises |

|---|---|---|---|

| Portée | S'applique aux équipements utilisés en atmosphères potentiellement explosives au sein de l'Union européenne. | Système de certification international reconnu dans plus de 30 pays à travers le monde. | Norme nationale relative aux équipements antidéflagrants utilisés dans les industries nationales chinoises. |

| Autorité de régulation | Commission européenne et organismes notifiés autorisés. | Commission électrotechnique internationale (CEI) par l'intermédiaire d'organismes de certification agréés (ExCB). | Administration d'État pour la réglementation du marché (SAMR) et Centre de certification CNEx. |

| Classification des zones dangereuses | Zones 0, 1, 2 (Gaz) ; Zones 20, 21, 22 (Poussières). | Zones 0, 1, 2 (Gaz) ; Zones 20, 21, 22 (Poussières). | Zones 0, 1, 2 (Gaz) ; Zones 20, 21, 22 (Poussières). |

| Méthodes de protection | Ex d (Antidéflagrant), Ex i (Sécurité intrinsèque), Ex e (Sécurité accrue), Ex m, Ex t. | Ex d, Ex i, Ex e, Ex m, Ex tb (Étanchéité à la poussière), Ex p (Pressurisation). | Ex d, Ex i, Ex e, Ex n — adaptés aux conditions d'humidité et de température élevées. |

| Processus de certification | Tests réalisés par des organismes notifiés de l'UE ; marquage CE et « Ex » obligatoire. | Testé par des laboratoires agréés IECEx ; certificat de conformité IECEx délivré. | Tests effectués par des laboratoires chinois agréés ; certification CNEx requise. |

| Reconnaissance | Valable dans toute l'UE ; reconnaissance partielle à l'international. | Reconnue mondialement dans les économies membres sans nouveau test. | Obligatoire en Chine ; reconnaissance limitée hors de Chine. |

| Certification du personnel | Non requis sous ATEX. | Requis dans le cadre du programme de compétences du personnel IECEx (IECEx 05). | Non requis ; axé sur la certification du produit. |

| Exemple de notation | Ex II 2G IIB T4 (pour atmosphères gazeuses). | Ex d IIC T4 Gb (pour la conformité globale). | Ex d IIC T4 Gb (certifié CNEx pour une utilisation en Chine). |

| Industries primaires | Pétrole et gaz, chimie, secteur maritime et centrales électriques au sein de l'UE. | Projets miniers, énergétiques et pétrochimiques mondiaux. | Raffineries, mines, sidérurgie et industrie manufacturière en Chine. |

Cadre réglementaire et portée

Comparaison des exigences techniques

Calendrier et coûts de la certification

Durée typique : 8 à 12 semaines Facteurs de coût : frais de l’organisme notifié, préparation de la documentation technique Avantage concurrentiel : essentiel pour l’accès au marché de l’UE

Durée typique : 6 à 10 semaines Facteurs de coût : Frais de laboratoire d’analyse, documentation internationale Avantage concurrentiel : Acceptation mondiale simplifiée

Durée typique : 10 à 16 semaines Facteurs de coût : exigences locales en matière de tests, services de traduction Avantage concurrentiel : indispensable pour entrer sur le marché chinois

Critères de sélection des grues antidéflagrantes

Évaluation de l'environnement opérationnel

Substances inflammables spécifiques présentes (classification des groupes de gaz) Propriétés et niveaux de concentration des poussières Facteurs environnementaux (température, humidité, potentiel de corrosion)

Paramètres opérationnels

Cycle de service et fréquence d'utilisation de la grue Accessibilité et intervalles de maintenance Protocoles d'intervention d'urgence et itinéraires d'évacuation

Exigences de conformité réglementaire

- Réglementation locale :Respect obligatoire des normes régionales sur les lieux d'installation des équipements

- Expansion future :Territoires opérationnels prévus nécessitant des certifications supplémentaires

- Exigences spécifiques à l'industrie :Réglementations sectorielles (par exemple, pétrole, chimie, produits pharmaceutiques)

Facteurs de compatibilité technique

- Systèmes électriques :Compatibilité en matière de tension, de fréquence et de système de protection

- Interfaces de contrôle :Intégration aux systèmes d'automatisation et de sécurité existants

- Dimensions physiques :Contraintes spatiales et exigences d'installation

Intégration dans des applications de grues réelles

Les grues antidéflagrantes sont indispensables dans des secteurs tels que :

raffineries pétrochimiques (ATEX) : des ponts roulants à double poutre de 50 tonnes manipulent des réacteurs sous pression.

opérations minières (IECEx) : Les monte-charges souterrains avec commandes Ex i gèrent les puits chargés de méthane.

Usines sidérurgiques et cimentières (GB) : Les portiques avec protection anti-poussière Ex tb assurent une manutention sûre des vracs.

Les systèmes éprouvés sur le terrain de KRC, comme ses Ponts roulants de style européen et treuils industriels personnalisés—sont adaptables à tout environnement dangereux, garantissant une conformité mondiale et une fiabilité opérationnelle.

Tendances futures des normes antidéflagrantes

Initiatives d'harmonisation

Les organismes internationaux de normalisation œuvrent à une plus grande harmonisation entre les normes ATEX, IECEx et GB. Nous participons activement à ces initiatives par le biais de groupes de travail sectoriels, afin de garantir que la conception de nos équipements anticipe l'évolution des exigences réglementaires. Organisation internationale de normalisation L’ISO publie des normes de sécurité régulièrement mises à jour et pertinentes pour les fabricants de grues.