Overhead bridge cranes are essential for material handling in workshops, warehouses, and industrial facilities. A fundamental choice when selecting one is deciding between a single girder or double girder design. Understanding their differences is crucial for making an informed, cost-effective decision that meets your operational needs.

This article breaks down the key distinctions in structure, capacity, application, and cost.

1.Main Girder Structure and Design

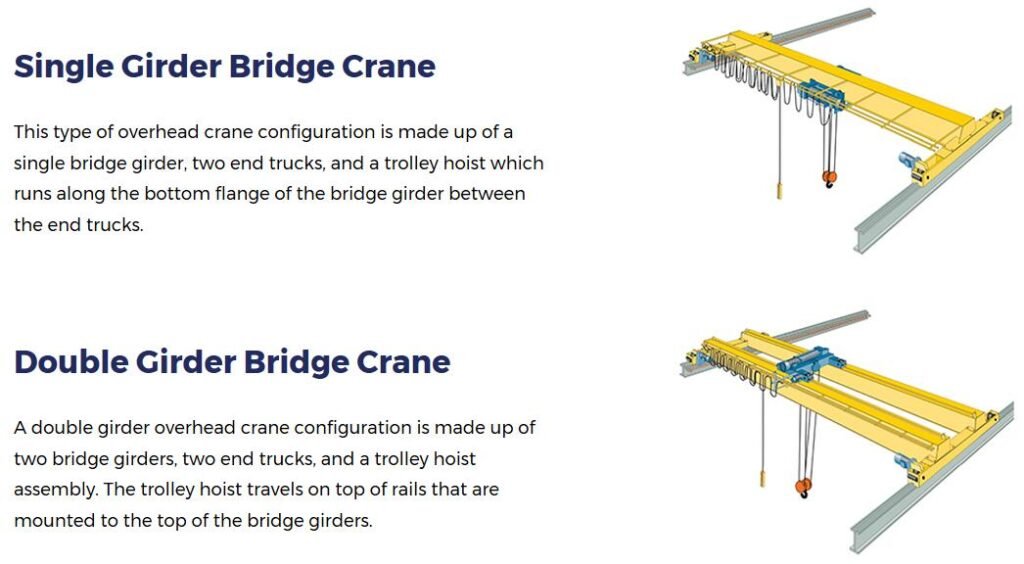

The most obvious difference lies in the number of main girders that form the bridge.

- Single Girder Crane: As the name implies, this design features a single main beam, typically made from a rolled steel I-beam or a fabricated box girder. The hoist trolley runs on the bottom flange of this single girder. This results in a lighter overall structure and a lower headroom (the distance from the hook to the ceiling).

- Double Girder Crane: This design incorporates two main girders connected by end trucks. The trolley and hoist run on a rail mounted on top of the two girders. This robust construction offers superior strength and rigidity, often with a pre-designed camber (upward deflection) to counteract deflection under heavy loads, ensuring smooth travel.

Key Takeaway: Double girder cranes have a more robust structure designed for heavier loads and longer spans.

2. Lifting Capacity and Span Length

The structural design directly impacts the crane’s performance capabilities.

- Single Girder Cranes: Best suited for light to medium-duty applications. They are typically ideal for capacities up to 20 tons and span lengths up to 30 meters. For heavier loads or longer spans, the single beam may deflect excessively.

- Double Girder Cranes: Engineered for heavy-duty and severe-duty cycles. They can handle capacities from 5 tons up to several hundred tons (e.g., our 320-ton Gantry Crane) and can be designed for much longer spans exceeding 30 meters.

Key Takeaway: Choose a double girder crane for heavier loads (>20 tons) and longer spans.

3. Hoist Trolley and Headroom

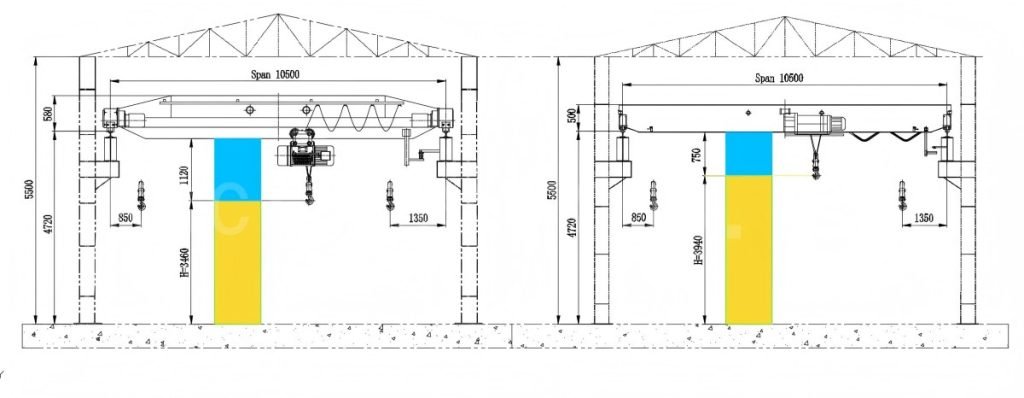

This is a critical differentiator for facilities with height constraints.

- Single Girder Crane: The hoist is suspended from the bottom of the single girder. This configuration provides maximum hook height as it requires less headroom between the crane and the ceiling. This is a major advantage in low-clearance buildings.

- Double Girder Crane: The trolley runs between the two girders on a top-mounted rail. This requires more vertical space, resulting in a higher headroom and a slightly lower hook height compared to a single girder crane with the same runway height.

Key Takeaway: Single girder cranes offer better hook height in low-clearance buildings.

4. Applications and Usage Scenarios

The choice often comes down to the specific application and workload.

- Single Girder Cranes: Perfect for workshops, warehouses, and logistics centers where loads are lighter, duty cycles are less frequent, and budget is a primary concern. They are excellent for general maintenance, loading/unloading, and machine feeding. Explore our European Single Girder Cranes for efficient solutions.

- Double Girder Cranes: Essential for heavy industries like steel processing, power plants, shipping ports, and paper mills. They are built for continuous, high-capacity lifting, often equipped with advanced controls and specialized below-hook attachments like Crane Lifting Magnetsor grabs.

5. Cost and Maintenance

- Initial Cost: Single girder cranes have a lower initial investment due to simpler design, less material, and easier installation.

- Long-Term Value: Double girder cranes, while more expensive upfront, offer greater durability, higher performance, and longer lifespan in demanding environments, providing better value for heavy-duty applications.

For all crane types, a robust Overhead Crane Maintenance program is vital for safety and longevity.

Summary: Which One Should You Choose?

Fonctionnalité | Single Girder Crane | Double Girder Crane |

|---|---|---|

Structure | One main beam | Two main beams |

Capacity | Up to 20 tons | 5 tons to 500+ tons |

Span Length | Up to ~30m | ~10m to 50m+ |

Headroom | Lower Headroom (Higher Hook) | Higher Headroom |

Cost | Lower Initial Cost | Higher Initial Cost |

Best For | Workshops, Warehouses, Light Duty | Heavy Industry, Ports, Severe Duty |

Conclusion: There is no universal “best” option. The right crane depends entirely on your specific requirements.

- For lighter loads, limited space, and a tighter budget, a single girder crane is likely the optimal choice.

- For heavy loads, long spans, and intense, continuous operation, a double girder crane is the necessary and reliable solution.

Still unsure? Our experts are here to help. Contact us today for a free consultation and to discuss your specific project needs.