Collaboration sino-allemande

Pont roulant bipoutre de type européen

Conçu pour la précision et les performances intensives

Caractéristiques principales

- Technologie allemande:Conception optimisée avec faible hauteur libre, structure légère et pression de roue réduite, minimisant l'investissement en usine.

- Contrôle de fréquence variable: Plusieurs options de vitesse pour un levage et un mouvement précis (levage de 0,4 à 16 m/min, chariot de 3 à 30 m/min).

- Alimentation électrique fiable:Les câbles plats à haute flexibilité et les rails de type C éliminent les risques de rupture de fil.

- Sécurité renforcée:Des dispositifs anti-déraillement électroniques et mécaniques assurent un fonctionnement fiable.

- Fonctionnement synchronisé: Liaison à double grue pour un fonctionnement, un levage et un positionnement précis synchronisés.

Applications

Conçu pour la polyvalence dans les environnements exigeants :

- Industrie chimique:Manipulation sécuritaire des matières dangereuses.

- Métallurgie:Levage robuste pour composants métalliques lourds.

- Automobile: Positionnement précis pour les grandes pièces.

- Chemin de fer:Approuvé par le CRRC pour l'assemblage de locomotives.

Spécifications techniques

| Paramètre | Spécification |

|---|---|

| Capacité de levage | Jusqu'à 800 tonnes |

| Portée | Jusqu'à 49 m |

| Vitesse de levage | 0,4-16 m/min |

| Vitesse de déplacement du chariot | 3-30 m/min |

| Vitesse de déplacement de la grue | 5-90 m/min |

| Système de contrôle | Contrôle de fréquence variable, fonctionnement synchronisé |

| Alimentation électrique | 380V/50Hz (personnalisable) |

Remarque : tous les paramètres peuvent être personnalisés pour répondre à votre site et à vos conditions de travail spécifiques.

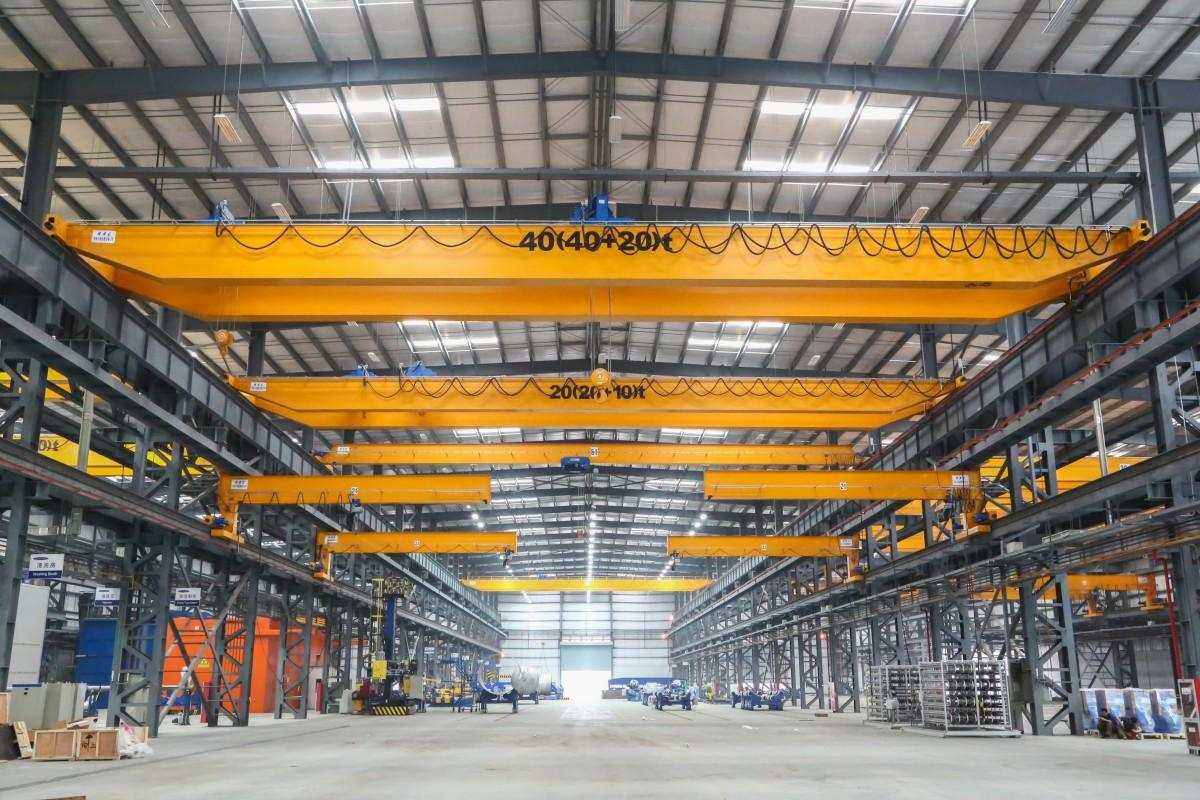

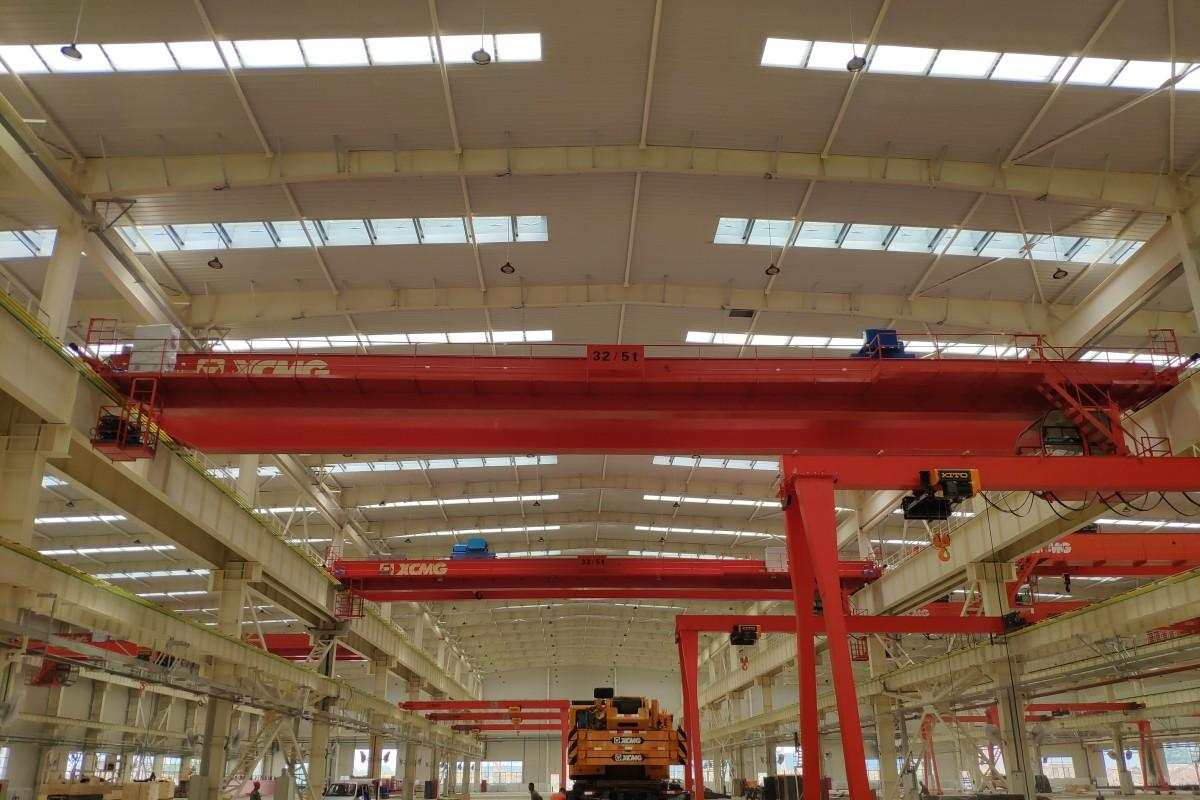

Cas réels

processus de production

Équipe de R&D professionnelle

Tous les ingénieurs sont formés professionnellement par ABUS (Allemagne) et utilisent des outils avancés de CAO 3D et d'analyse par éléments finis (FEA) pour simuler la répartition des contraintes et le mouvement de chaque système de grue.

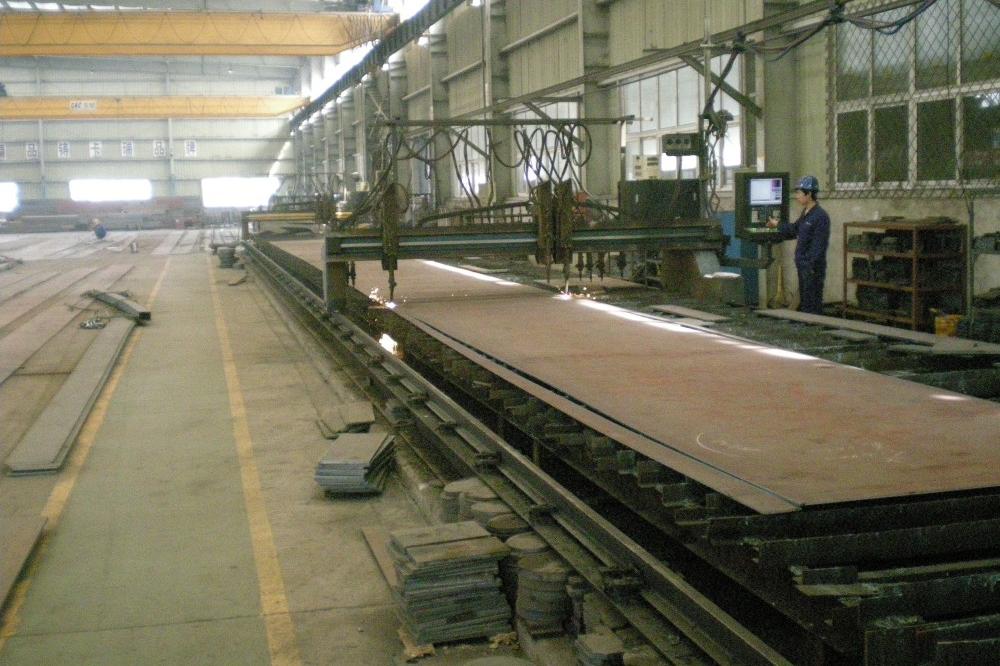

Système de découpe plasma CNC

La découpe automatisée de tous les composants de forme personnalisée garantit une précision dimensionnelle élevée et une cohérence sur tous les équipements de levage.

Machine de découpe au chalumeau CNC de 40 m

Toutes les tôles d'âme sont découpées avec précision en une seule passe grâce à la technologie CNC, garantissant des courbes de cambrure précises. La découpe manuelle au gaz est interdite ; seules les machines CNC ou des outils spécialisés sont utilisés pour les formes irrégulières.

Plieuse CNC WEH 2500 mm 400 tonnes

Utilisé pour le formage détaillé de petits composants de grue, garantissant un façonnage précis et une apparence finale haut de gamme.

Aléseuse et fraiseuse horizontale CNC

Avec une course de 8 mètres et un contrôle complet par micro-ordinateur, l'usinage des poutres d'extrémité est réalisé en une seule configuration pour garantir une rectitude stricte de l'alignement des roues et d'autres tolérances critiques.

Centres d'usinage verticaux série VMC

Les processus programmés par CNC garantissent une fabrication de pièces de haute précision, garantissant une excellente précision d'assemblage et une qualité globale du produit.

Ligne de grenaillage entièrement automatique de 60 m

Chaque poutre de grue est soumise à un grenaillage après soudage. Ce procédé élimine l'oxydation, améliore l'adhérence de la peinture et élimine les contraintes résiduelles, prolongeant ainsi la durée de vie de la structure.

Cabine de peinture au pistolet ZS

Tous les composants de nos palans électriques à câble sont recouverts d'une peinture polyuréthane haute performance, garantissant une finition durable et attrayante.

Bancs d'essai pour palans et chariots

Les palans et chariots électriques 100% sont alimentés et testés individuellement pour garantir une fonctionnalité et une conformité complètes avant de quitter l'usine.

Plateforme de test du système complet

Chaque grue non standard ou nouvellement développée est soumise à des tests de performance complets sur notre banc d'essai complet dédié avant la livraison.

Contactez-nous pour un devis

Optimisez vos opérations de levage grâce aux solutions d'ingénierie allemande de KRC. Contactez-nous dès aujourd'hui !