Colaboração Sino-Alemã

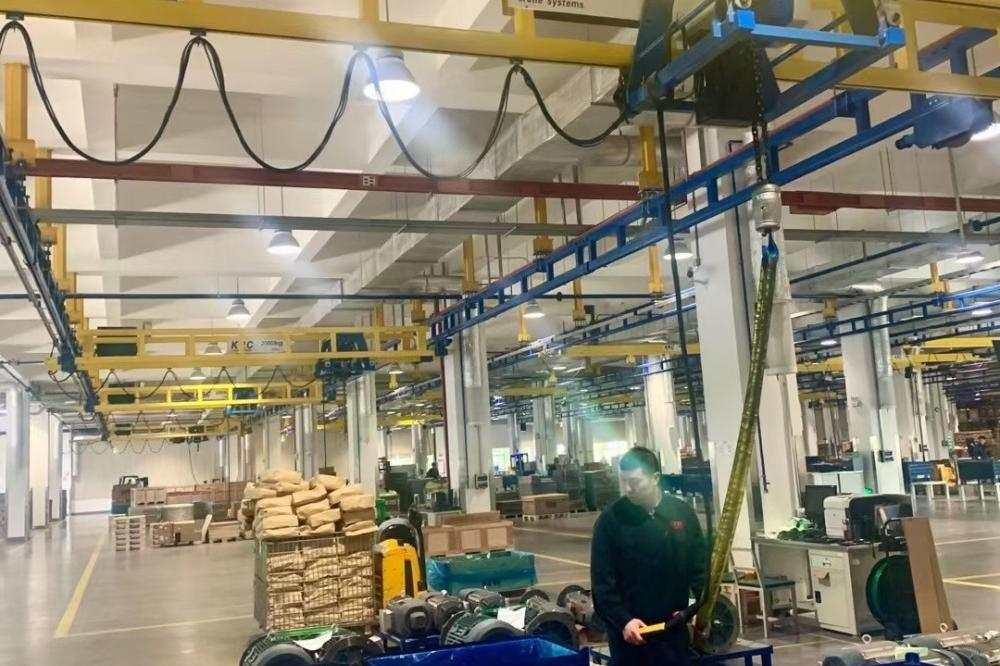

Sistema de guindaste leve KRC KBK

Sistemas de esteiras versáteis, rígidas e flexíveis para elevação precisa de até 2.000 kg, ideais para aplicações de fabricação, automotivas e de armazenagem.

Sobre a KRC Factory

Fundada em 1998 em Luoyang, a Karui Lifting Equipment Co., Ltd. (KRC) é líder em guindastes inteligentes e de estilo europeu, em colaboração com a ABUS, principal fabricante de guindastes da Alemanha. Com mais de 20 tecnologias patenteadas e qualificações de nível A, a KRC contribui para o *Manual de Projeto de Guindastes* e as Normas Chinesas para Guindastes. Nossa fábrica produziu um guindaste de viga dupla de 360 toneladas e 34,5 m de vão, um recorde, atendendo setores como manufatura, automotivo e armazenagem com soluções personalizadas.

- Capacidade máxima: 2000 kg | Vão máximo: 10 m

- Projetos patenteados: mais de 20 inovações em eficiência estrutural

- Arquitetura de sistema duplo: configurações de trilhos rígidos e flexíveis

Sistema de guindaste leve KBK

O sistema de guindaste leve KBK da KRC, equipado com tecnologia ABUS, oferece esteiras rígidas e flexíveis com capacidade de até 2.000 kg e vão de 10 m para elevação versátil.

Sistemas de trilhos rígidos

Projetado para estabilidade e desempenho em serviços pesados

- Capacidade de 2000 kg | vão de 10 m

- Design discreto para espaços com restrição de altura

- Vida útil prolongada com manutenção mínima

Variações do sistema:

- Guindastes autopropelidos:

- Trilhos reforçados ou configurações treliçadas para maior espaçamento de suporte.

- Guindastes Suspensos:

- Trilhos padrão (otimizados em termos de espaço) vs. trilhos treliçados (pontos de suspensão reduzidos).

- Sistemas Multi-Feixe:

- Trilhas paralelas equipadas com buffer para operações simultâneas.

- Sistemas Telescópicos:

- Cobertura estendida para carregamento de contêineres/caminhões e ferramentas automotivas.

- Guindastes de lança:

- Rotação de 180° | Capacidade de 1000 kg | Segurança em trilho fechado.

Especificações técnicas:

| Tamanho | Perfil da pista (mm) | hum) | b (mm) | d (mm) |

|---|---|---|---|---|

| EU | 60.00 | 65.00 | 18.00 | 3.60 |

| II | 75.00 | 80.00 | 22.00 | 4.50 |

| III | 110.00 | 90.00 | 25.00 | 6.50 |

Sistemas de trilhos flexíveis

Soluções adaptáveis para fluxos de trabalho dinâmicos

- Monotrilho YKR-M:

125-1000 kg| Montagem rápida de módulos | Compatibilidade com guincho universal. - Viga única YKR-S:

125-1000 kg| Design 3D antibalanço | Raio operacional máximo. - Viga Dupla YKR-D:

125-2000 kg| Posicionamento central do guincho | Distância vertical ideal.

Casos reais

processo de produção

Equipe profissional de P&D

Todos os engenheiros são treinados profissionalmente pela ABUS (Alemanha) e utilizam ferramentas avançadas de CAD 3D e análise de elementos finitos (FEA) para simular a distribuição de tensão e movimento de cada sistema de guindaste.

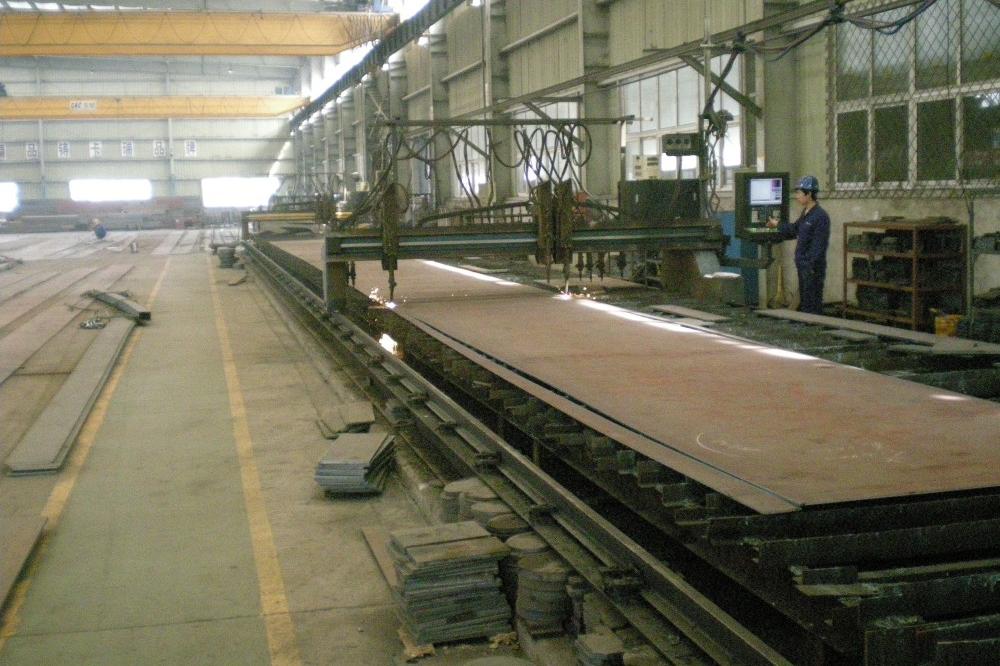

Sistema de corte de plasma CNC

O corte automatizado de todos os componentes com formato personalizado garante alta precisão dimensional e consistência em todos os equipamentos de elevação.

Máquina de corte a chama CNC de 40 m

Todas as chapas de alma são cortadas com precisão em uma única passagem usando tecnologia CNC, garantindo curvas de cambagem precisas. Não é permitido corte manual a gás — apenas CNC ou ferramentas especializadas são usadas para formas irregulares.

Máquina de dobra CNC WEH de 2500 mm e 400 T

Usado para conformação detalhada de pequenos componentes de guindaste, garantindo modelagem precisa e uma aparência final premium.

Máquina de furação e fresagem horizontal CNC

Com curso de 8 metros e controle total do microcomputador, a usinagem da viga final é concluída em uma única configuração para garantir a retidão rigorosa do alinhamento das rodas e outras tolerâncias críticas.

Centros de usinagem verticais da série VMC

Os processos programados por CNC garantem a fabricação de peças de alta precisão, assegurando excelente precisão de montagem e qualidade geral do produto.

Linha de jateamento totalmente automática de 60 m

Todas as vigas de guindaste passam por jateamento após a soldagem. Esse processo remove a oxidação, melhora a aderência da tinta e elimina tensões residuais, prolongando a vida útil da estrutura.

Cabine de pintura spray ZS

Todos os componentes dos nossos talhos elétricos de cabo são revestidos com tinta de poliuretano de alto desempenho, garantindo um acabamento durável e atraente.

Bancadas de teste para guinchos e carrinhos

Os guindastes e carrinhos elétricos 100% são energizados e testados individualmente para garantir total funcionalidade e conformidade antes de saírem da fábrica.

Plataforma de teste de sistema completo

Cada guindaste não padronizado ou recém-desenvolvido passa por testes de desempenho abrangentes em nosso banco de testes dedicado de sistema completo antes da entrega.

Entre em contato conosco para um orçamento

Aprimore suas operações de elevação com as soluções de engenharia alemã da KRC. Entre em contato conosco hoje mesmo!