Feature

- Versatile Application: Suitable for dams, reservoirs, irrigation systems, flood control, hydropower stations, ship locks, and sewage treatment plants.

- Manual, Electric, & Hydraulic Models: Options to suit different operational needs and preferences.

- Robust Construction: Made with durable materials to withstand harsh environments.

- High Load Capacity: Capable of handling large gates with ease.

- Flexible Operation: Wire rope can be wound in single or multiple layers for different gate sizes and strokes.

- Safety Features: Includes brakes, speed reducers, and safety devices for secure operation.

- Customizable: Adjustable for various orifice sizes, heads, and directional forces.

- Quick Response: Electric models offer rapid gate opening and closing, ideal for emergencies.

- Corrosion Resistant: Suitable for long-term use in challenging conditions.

- Remote Control Options: Available for convenient and efficient operation.

Product Description

Our high-performance Sluice Gate Hoists are engineered to provide reliable and efficient control over water flow and levels across various water management systems. These versatile gate hoists are essential for applications in water conservancy projects such as dams, reservoirs, and sluices, as well as in irrigation systems, flood control projects, hydropower stations, ship locks, and sewage treatment plants.

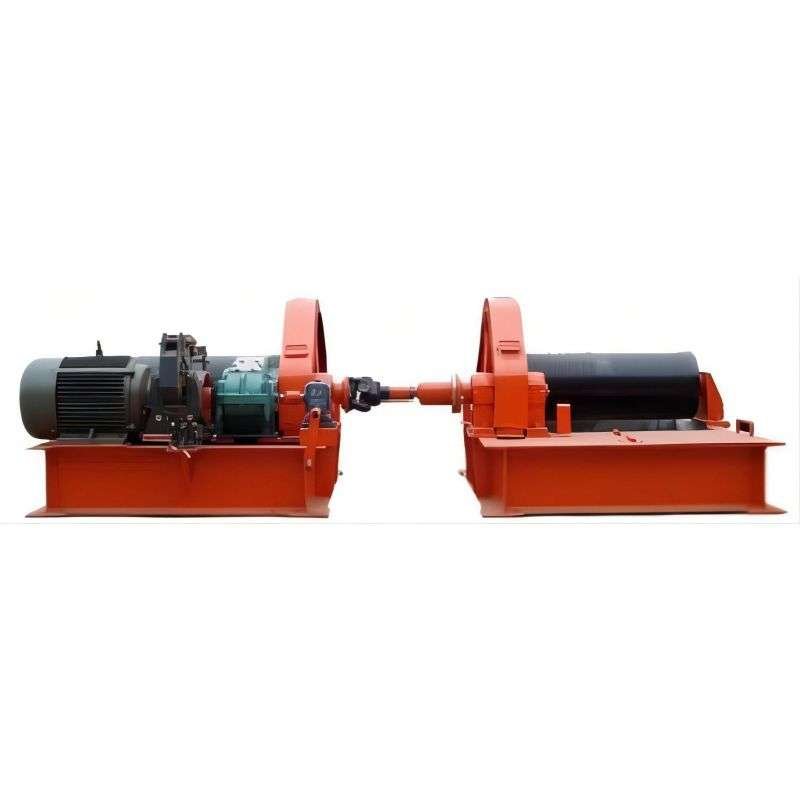

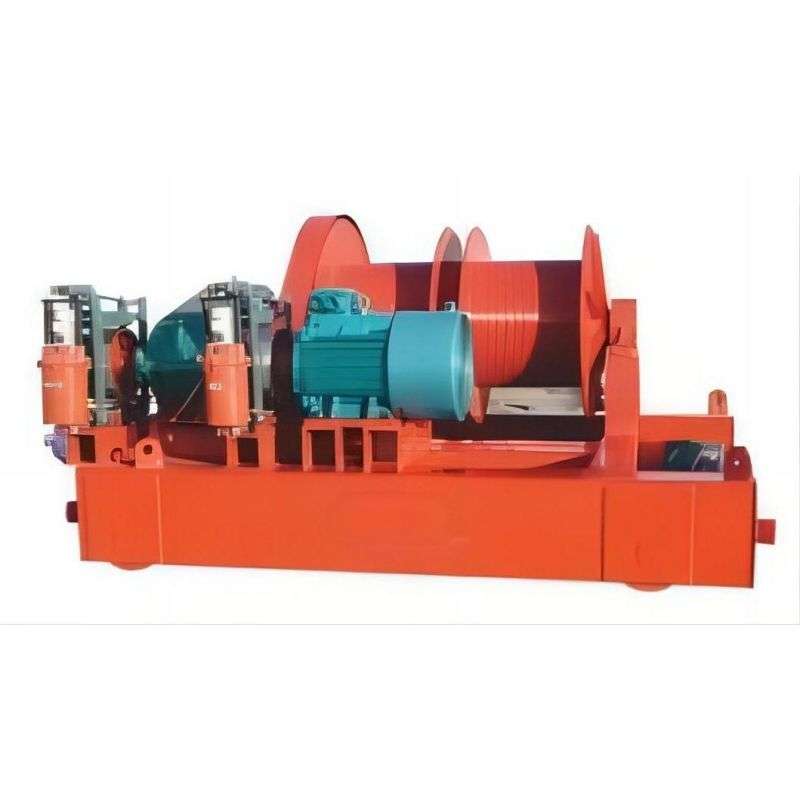

The robust construction of our gate hoists ensures durability and longevity, even in harsh environments. Each hoist comprises a sturdy frame, a sophisticated hoisting mechanism, and an advanced electrical control system. The arc door winch opening and closing mechanism includes a pulley block, reel set, driving device (featuring a gear pair, speed reducer, brake, motor, etc.), and a safety device. This setup guarantees smooth and efficient gate operation, with the hoist connected to the gates through a spreader located on the pulley assembly.

The working principle of our sluice gate hoists involves the motor driving the brake wheel and reducer, which in turn drives the gear pair and reel. The wire rope on the reel is lifted and lowered by the pulley and balance pulley system, enabling precise control over gate movement. This flexibility allows the wire rope’s force direction to be adjusted appropriately or changed using an additional embedded diverting pulley, offering greater operational flexibility.

In water conservancy projects, our sluice gate hoists regulate the opening and closing of gates to control water levels and flow. In irrigation systems, these hoists manage the gates of irrigation channels, facilitating efficient farmland irrigation. During flood periods, they adjust gate positions to control flood flow, reducing the impact on downstream areas.

In hydropower stations, our hoists control the gates at the intake and outlet points to manage water flow and power generation. For ship locks, they enable the navigation of vessels by controlling gate positions. Additionally, in sewage treatment plants, these hoists regulate gates at inlet and outlet points, ensuring proper sewage flow and treatment processes.

Electric gate hoists offer rapid opening and closing, making them suitable for emergency gates and frequently operated gates. The inclusion of speed reducers and brakes enhances safety and precision, while the robust construction ensures long-lasting performance even in demanding environments.

Our gate hoists are customizable to meet specific project requirements, with options for different orifice sizes, heads, and directional force adjustments. This flexibility makes them the ideal choice for a wide range of water management applications.