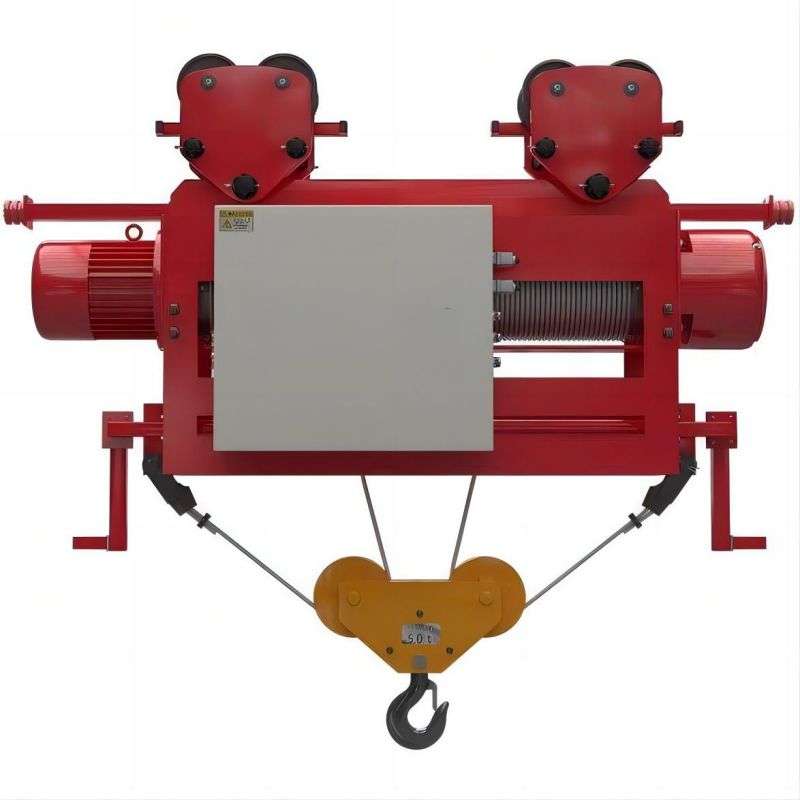

Detailed Images

Feature

- High Protection Levels: Offers IP44, IP54, and IP55 protection levels with customizable insulation.

- Surface Anti-Corrosion Treatment: Epoxy zinc-rich anti-corrosion paint and galvanized surface provide enhanced durability.

- Four-Rope, One-Line Structure: Suitable for pickling workshops and heavy-duty lifting needs.

- Customizable Work Levels: M3/M4 grade for demanding applications.

- Curved Track Capability: Ideal for assembly line operations.

- Remote or Fully Automatic Operation: Flexibility in control methods.

- Parallel Straight Rope Winding Method: Provides better force distribution and stability.

- Energy-Efficient Operation: Reduces energy consumption while increasing productivity.

- Customizable Functions: Special anti-corrosion, acid/alkali resistance, and anti-collision features available.

Product Description

The Pickling and Galvanizing Wire Rope Electric Hoist, also known as the Galvanized Pickled Wire Rope Electric Hoist, is specially designed to meet the demands of the pickling and galvanizing industries. The unique square box design and four-rope, one-line structure ensure exceptional anti-corrosion performance while reducing labor intensity and improving worker safety.

The anti-corrosion treatment includes surface shot blasting and epoxy zinc-rich anti-corrosion paint, enhancing the durability of this Pickled Galvanized Wire Rope Lifting Hoist. The high protection levels (IP44, IP54, and IP55) and Class F insulation make this Industrial Pickling Galvanizing Electric Hoist suitable for harsh environments.

The Pickling and Galvanizing Crane Hoist offers parallel straight rope winding, providing superior force distribution and stability. With lifting capacities ranging from 2t to 10t and lifting heights up to 12 meters, it is adaptable to various heavy-duty lifting needs.

Available in M3/M4 grades, this Industrial Grade Pickled Galvanized Hoist is ideal for applications in assembly lines, electroplating, and heavy lifting in corrosive environments. Its energy-efficient operation reduces energy consumption and production costs, while the customizable functions such as special anti-corrosion, acid/alkali resistance, and anti-collision features meet specific industrial requirements.

| Specification | 2t | 3t | 5t | 10t |

|---|---|---|---|---|

| Lifting Height (m) | 6-12 | 6-12 | 6-12 | 6-12 |

| Parallel Straight Rope | 2/4 | 2/4 | 2/4 | 2/4 |

| Lifting Speed (m/min) | 8 (0.8/8) | 8 (0.8/8) | 8 (0.8/8) | 7 (0.7/7) |

| Lifting Power (kW) | 3.0 | 4.5 | 7.5 | 13 |

| Running Speed (m/min) | 0-20 | 0-30 | 0-20 | 0-30 |

| Operating Power (kW) | 0.4*2 | 0.4*2 | 0.8*2 | 0.8*2 |

| Wire Rope | IWR | IWR | IWR | IWR |

| Protection Level | IP44/54/55 | IP44/54/55 | IP44/54/55 | IP44/54/55 |

| Insulation Level | Class F | Class F | Class F | Class F |

| Operation Method | Remote/Auto | Remote/Auto | Remote/Auto | Remote/Auto |

| Job Grade | M3/M4 | M3/M4 | M3/M4 | M3/M4 |

| Power Supply | 3P 380V 50HZ | 3P 380V 50HZ | 3P 380V 50HZ | 3P 380V 50HZ |

| Remarks | Special Anti-Corrosion, Acid/Alkali Resistant, Anti-Collision Functions Available |