Collaboration sino-allemande

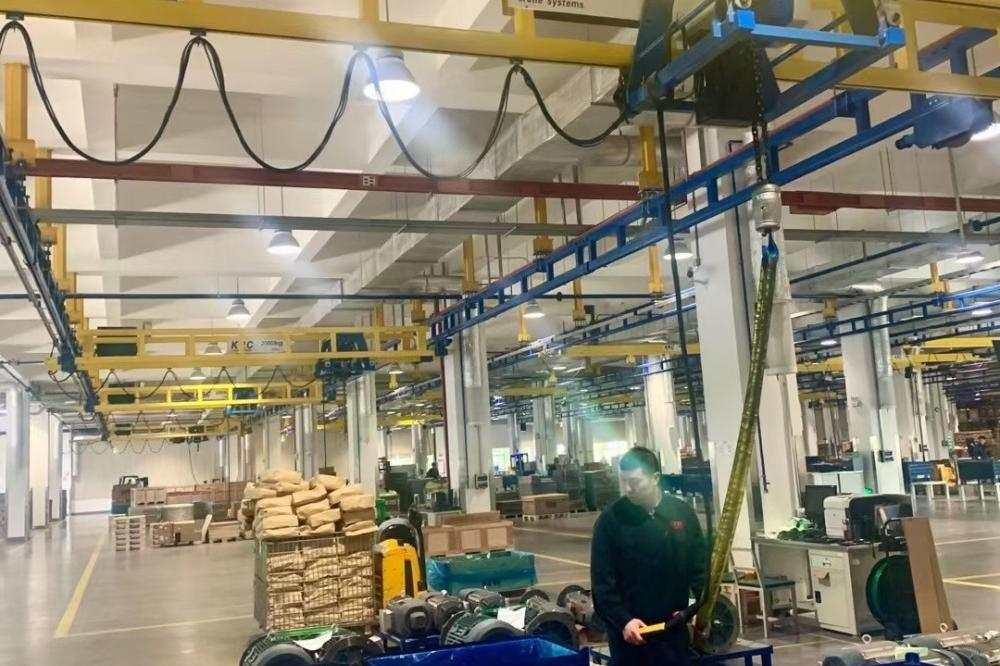

Système de grue légère KRC KBK

Systèmes de chenilles rigides et flexibles polyvalents pour un levage précis jusqu'à 2000 kg, idéaux pour les applications de fabrication, d'automobile et d'entreposage.

À propos de l'usine KRC

Fondée en 1998 à Luoyang, Karui Lifting Equipment Co., Ltd. (KRC) est un leader des grues intelligentes de style européen, en collaboration avec ABUS, premier fabricant allemand de grues. Avec plus de 20 technologies brevetées et des qualifications de classe A, KRC contribue au Manuel de conception des grues et aux normes chinoises relatives aux grues. Notre usine a produit une grue bipoutre record de 360 tonnes et de 34,5 m de portée, offrant des solutions sur mesure à des secteurs tels que la fabrication, l'automobile et l'entreposage.

- Capacité maximale : 2 000 kg | Portée maximale : 10 m

- Conceptions brevetées : plus de 20 innovations en matière d'efficacité structurelle

- Architecture à double système : configurations de voies rigides et flexibles

Système de grue légère KBK

Le système de grue légère KBK de KRC, alimenté par la technologie ABUS, offre des chenilles rigides et flexibles d'une capacité allant jusqu'à 2 000 kg et d'une portée de 10 m pour un levage polyvalent.

Systèmes de chenilles rigides

Conçu pour la stabilité et les performances à toute épreuve

- Capacité de 2 000 kg | Portée de 10 m

- Conception à profil bas pour les espaces à hauteur limitée

- Durée de vie prolongée avec un entretien minimal

Variations du système :

- Grues automotrices :

- Rails renforcés ou configurations en treillis pour un espacement de support accru.

- Grues suspendues :

- Rails standards (optimisés en termes d'espace) vs. rails à treillis (points de suspension réduits).

- Systèmes multifaisceaux :

- Voies parallèles équipées de tampons pour des opérations simultanées.

- Systèmes télescopiques :

- Couverture étendue pour le chargement de conteneurs/camions et l'outillage automobile.

- Grues à flèche :

- Rotation à 180° | Capacité de 1000 kg | Sécurité sur rail fermé.

Spécifications techniques :

| Taille | Profil de la piste (mm) | Hmm) | b (mm) | d (mm) |

|---|---|---|---|---|

| je | 60.00 | 65.00 | 18.00 | 3.60 |

| II | 75.00 | 80.00 | 22.00 | 4.50 |

| III | 110.00 | 90.00 | 25.00 | 6.50 |

Systèmes de rails flexibles

Solutions adaptables pour flux de travail dynamiques

- Monorail YKR-M :

125-1000 kg| Montage rapide des modules | Compatibilité universelle avec les palans. - Poutre unique YKR-S :

125-1000 kg| Conception 3D anti-balancement | Rayon opérationnel maximal. - YKR-D Bipoutre :

125-2000 kg| Positionnement central du palan | Dégagement vertical optimal.

Cas réels

processus de production

Équipe de R&D professionnelle

Tous les ingénieurs sont formés professionnellement par ABUS (Allemagne) et utilisent des outils avancés de CAO 3D et d'analyse par éléments finis (FEA) pour simuler la répartition des contraintes et le mouvement de chaque système de grue.

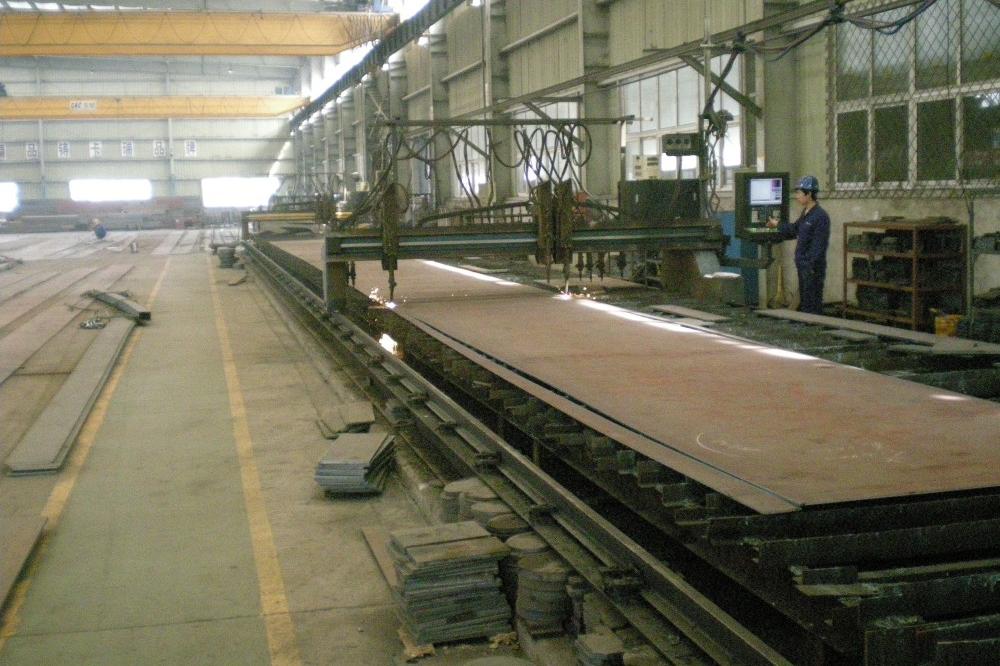

Système de découpe plasma CNC

La découpe automatisée de tous les composants de forme personnalisée garantit une précision dimensionnelle élevée et une cohérence sur tous les équipements de levage.

Machine de découpe au chalumeau CNC de 40 m

Toutes les tôles d'âme sont découpées avec précision en une seule passe grâce à la technologie CNC, garantissant des courbes de cambrure précises. La découpe manuelle au gaz est interdite ; seules les machines CNC ou des outils spécialisés sont utilisés pour les formes irrégulières.

Plieuse CNC WEH 2500 mm 400 tonnes

Utilisé pour le formage détaillé de petits composants de grue, garantissant un façonnage précis et une apparence finale haut de gamme.

Aléseuse et fraiseuse horizontale CNC

Avec une course de 8 mètres et un contrôle complet par micro-ordinateur, l'usinage des poutres d'extrémité est réalisé en une seule configuration pour garantir une rectitude stricte de l'alignement des roues et d'autres tolérances critiques.

Centres d'usinage verticaux série VMC

Les processus programmés par CNC garantissent une fabrication de pièces de haute précision, garantissant une excellente précision d'assemblage et une qualité globale du produit.

Ligne de grenaillage entièrement automatique de 60 m

Chaque poutre de grue est soumise à un grenaillage après soudage. Ce procédé élimine l'oxydation, améliore l'adhérence de la peinture et élimine les contraintes résiduelles, prolongeant ainsi la durée de vie de la structure.

Cabine de peinture au pistolet ZS

Tous les composants de nos palans électriques à câble sont recouverts d'une peinture polyuréthane haute performance, garantissant une finition durable et attrayante.

Bancs d'essai pour palans et chariots

Les palans et chariots électriques 100% sont alimentés et testés individuellement pour garantir une fonctionnalité et une conformité complètes avant de quitter l'usine.

Plateforme de test du système complet

Chaque grue non standard ou nouvellement développée est soumise à des tests de performance complets sur notre banc d'essai complet dédié avant la livraison.

Contactez-nous pour un devis

Optimisez vos opérations de levage grâce aux solutions d'ingénierie allemande de KRC. Contactez-nous dès aujourd'hui !